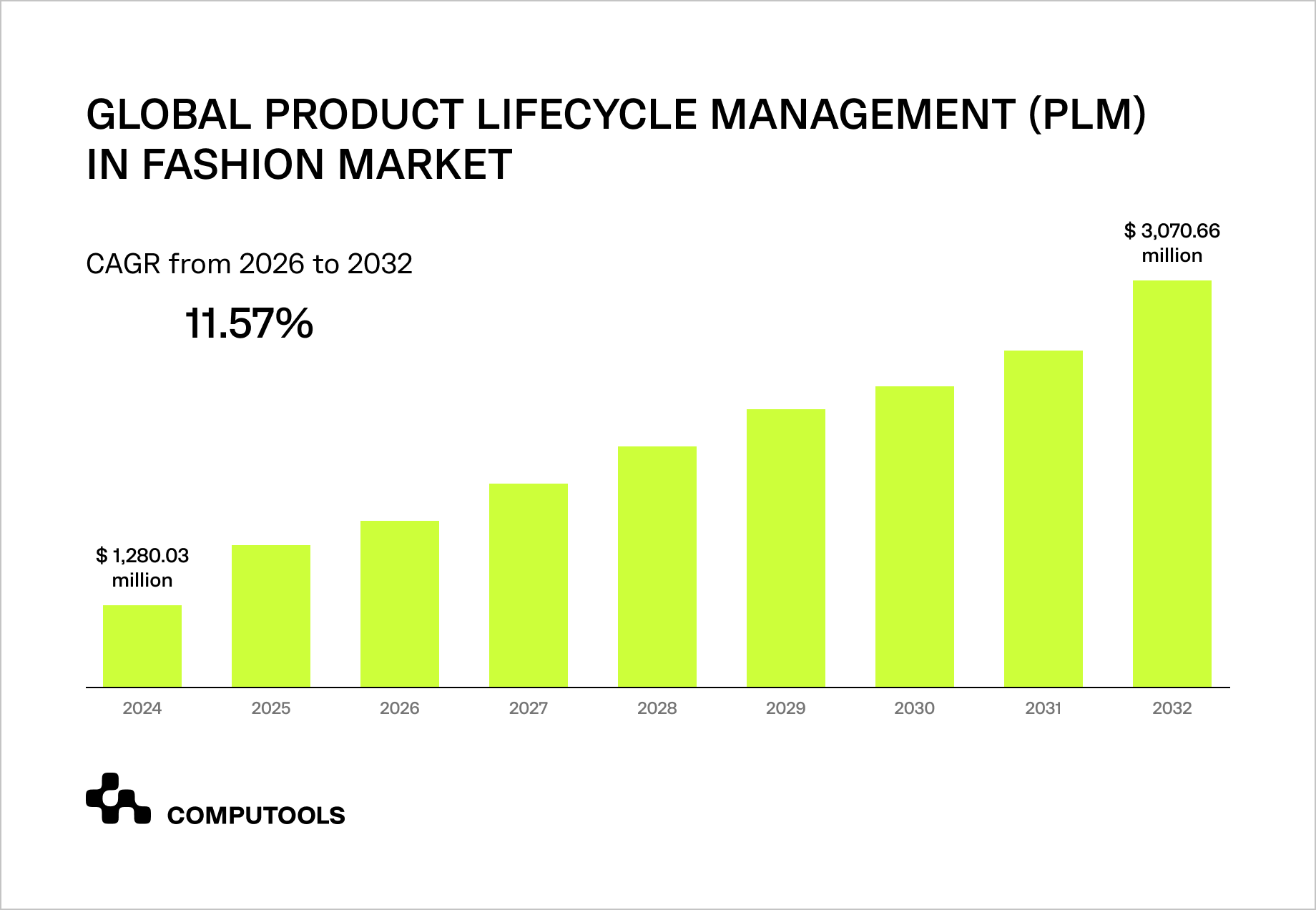

Fashion PLM integration has become increasingly critical as the market continues to grow rapidly. The Product Lifecycle Management (PLM) market in the fashion industry was valued at approximately USD 1.28 billion in 2024 and is projected to reach over USD 3.07 billion by 2032, growing at a 11.57% CAGR from 2026 to 2032.

Meanwhile, the fashion e-commerce sector is booming, with an expected $1.06 trillion in revenue by 2025, representing 48% of all fashion sales that now occur online.

However, this growth exposes serious operational pain points. 83% of e-commerce leaders report incomplete or inaccurate product data, resulting in 42% of cart abandonments and 42% of fashion returns due to misrepresented product details.

Meanwhile, 69% of customers abandon purchases when products are out of stock, and 34% of retailers struggle to sync inventory across channels. Disconnected systems cost brands up to 11% of annual revenue in lost sales and excess stock. This makes fashion and apparel software development, as well as PLM–eCommerce integration, critical for unifying product data, accelerating design, optimizing sourcing, and embedding AI-driven forecasting and sustainability features to reduce waste and shorten lead times.

At Computools, we’ve seen in practice how fragmented data and disconnected workflows slow teams down and limit growth. That’s why we built a unified solution that connects PLM systems for fashion industry with core retail operations, creating a single source of truth for product data, design, and production.

How we integrated PLM with eCommerce systems in fashion retail

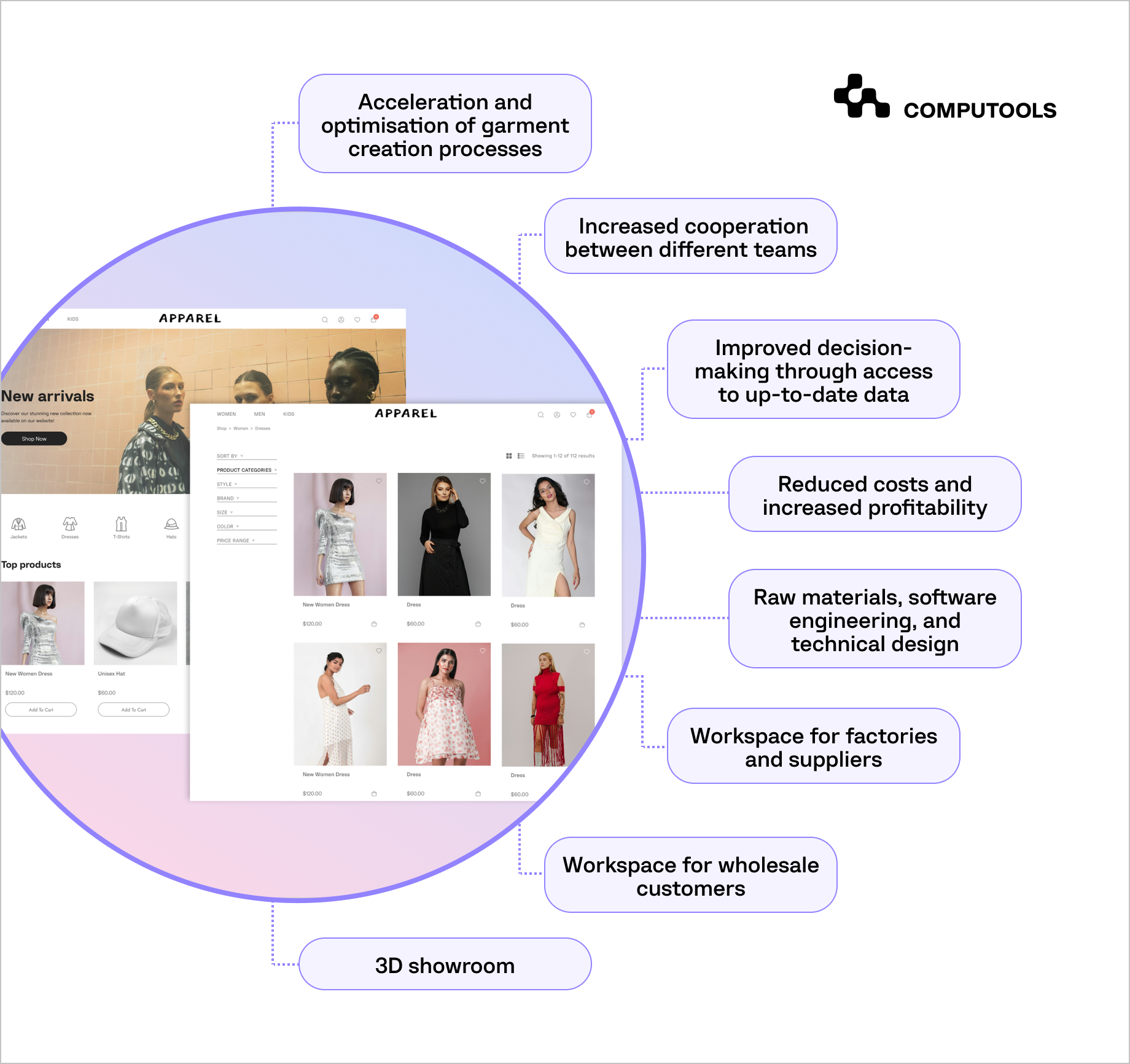

Through advanced eCommerce development services, we helped a global fashion brand develop and launch the Apparel Platform, a scalable digital ecosystem connecting merchandisers, designers, suppliers, and factories worldwide. The platform replaced fragmented spreadsheets and disconnected systems with a unified workspace that centralized product data, assortment planning, and visual presentations. This enabled teams to collaborate in real-time, streamline approvals, and maintain full visibility across the entire product lifecycle.

At the core of the solution was seamless connectivity with PLM systems for the fashion industry, ensuring continuous data synchronization between design, sourcing, and sales environments. Any update in the PLM from material specifications to seasonal pricing was instantly mirrored in the platform, eliminating manual input and aligning every department around a single, accurate source of truth.

The platform’s architecture, built on .NET and Angular, offered scalability and performance for global operations and seasonal peak demand. Modules such as Line Planning, Presentation, and Sandbox enable merchandisers to visualize assortments, simulate launches, and plan collections while maintaining data flow from PLM and ERP.

As a result, the client reduced time-to-market, strengthened collaboration, and cut down returns linked to inconsistent product data. This success became the foundation for more intelligent retail operations, proving that integrated digital ecosystems can transform how fashion businesses design, sell, and grow.

That’s why we’re sharing this guide: we’ve built it, tested it, and know exactly how PLM and eCommerce integration can redefine what’s possible in fashion retail.

How to integrate PLM with e-commerce systems in fashion retail

Now, we will explore how to integrate PLM with eCommerce systems in fashion retail, outlining actions to unify product data, streamline workflows, and speed up time-to-market.

1. Define Clear Goals for PLM Implementation

Before any technical work begins, fashion brands must clearly define what they expect to achieve with fashion PLM integration, whether that’s reducing time-to-market, improving visibility across teams, minimizing returns, or ensuring sustainability tracking. Setting specific, measurable goals helps determine the right system architecture and workflow design from the start.

Establishing clear KPIs such as sample approval speed, error reduction in product data, or percentage improvement in collaboration efficiency ensures that progress can be quantified, not just observed. Many successful projects begin with identifying which pain points consume the most resources and how a connected digital ecosystem can solve them.

In the Apparel case, Computools’ team began by mapping out the client’s complete design-to-production workflow to identify bottlenecks, primarily in manual approvals, duplicated data, and fragmented communication.

By developing a unified digital workspace through Fashion retail PLM software, the client gained a centralized environment where all product information, sketches, and specifications were updated in real time. This strategic clarity enabled smarter process automation and faster decision-making.

As a result, the client reduced collection development time, accelerated cross-departmental collaboration, and enhanced visibility from concept to launch. This first step, defining goals and aligning them with both PLM and business strategy, became the foundation for a scalable and future-ready integration.

2. Involve Cross-Functional Teams Early

A successful fashion PLM integration depends on technology, but mostly on people, specifically, how well teams across departments collaborate from the very beginning. Integrating PLM with eCommerce platforms impacts nearly every aspect of a retail organization, including design, merchandising, supply chain management, marketing, and IT. Each team views product data differently and relies on it for distinct decisions, from fabric selection and cost calculations to online product descriptions and digital merchandising.

Bringing all stakeholders together early ensures data fields, workflows, and approval processes meet everyone’s needs, avoiding costly revisions. Design teams define how creative assets flow into PLM; merchandisers set visibility rules for line planning, while IT and eCommerce ensure system interoperability and data integrity. This approach turns integration into a shared ecosystem rather than isolated tools.

In the Apparel project, Computools engaged merchandisers, designers, suppliers, and technology teams from day one. Regular workshops and prototype reviews helped capture requirements from all sides, ensuring seamless communication between creative and technical users. As a result, the final platform aligned perfectly with the client’s operational reality, connecting design updates directly to eCommerce listings, synchronizing assortment data, and minimizing post-launch adjustments.

Early collaboration improved adoption rates and also fostered a culture of shared ownership. Everyone, from designers to developers, could see how their input shaped a system that simplified daily work, improved accuracy, and ultimately accelerated time-to-market.

3. Choose a PLM System Tailored to Fashion

Not all PLM systems are built for the unique pace and complexity of the fashion industry. Generic tools often lack the flexibility and creative focus required for apparel design, where each season brings new materials, styles, and compliance standards. Choosing a fashion-specific PLM system means selecting software that understands how design decisions, production timelines, and retail performance interact in real time.

A modern PLM tailored for fashion should include modules for color and fabric management, 3D design integration, digital asset libraries, and automated tech pack generation. It must also seamlessly integrate with fashion eCommerce technology solutions, enabling product data to move directly from design to the digital shelf without duplication or loss of accuracy. This connection ensures that product visuals, specifications, and availability updates reach consumers instantly, maintaining consistency between the creative studio and the online store.

Computools developed a custom PLM layer for the Apparel case, purpose-built for apparel lifecycle management. This system enabled the client to track materials, sizes, fits, and sustainability indicators across all product lines, automatically updating eCommerce channels. Thanks to this tailored approach, the retailer achieved greater design control, faster digital merchandising, and a unified product narrative across every channel.

4. Build a Seamless Integration Architecture

Creating a smooth digital bridge between systems is where the true value of PLM connectors for eCommerce becomes clear. Once goals are defined and the right PLM system is selected, the next critical phase is establishing a robust integration framework that ensures real-time synchronization across all business layers from design and merchandising to online storefronts.

A well-built integration architecture relies on open APIs that enable secure, automated data exchange between PLM, ERP, and eCommerce environments. Each change in the PLM, whether a color adjustment, size update, or pricing revision, should instantly reflect in product listings, digital catalogs, and inventory dashboards. This eliminates duplication, reduces errors, and ensures that every customer-facing platform mirrors accurate, up-to-date information.

In the Apparel case, Computools built an API-based system linking the client’s PLM with eCommerce channels. It automatically synced product specs, visuals, and prices across marketplaces, reducing manual work and ensuring data accuracy. The integration supported regional differences, enabling simultaneous launches across markets with centralized control.

Implementing advanced PLM connectors enables brands to establish a scalable foundation for growth, supporting omnichannel expansion, expedited product launches, and enhanced alignment between creative and commercial teams. This technical infrastructure transforms once-fragmented workflows into a seamless, intelligent data ecosystem.

5. Ensure Real-Time Collaboration and Transparency

For modern fashion retailers, speed and clarity in communication are key to competitiveness. PLM for fashion brands goes beyond managing product data; it connects creative, technical, and commercial teams into a single real-time collaboration environment. When design, merchandising, and supply chain teams share the same live data, decisions happen faster, and costly errors are minimized.

A collaborative PLM setup replaces endless emails and outdated file exchanges with instant, trackable feedback loops. Every design update, material change, or merchandising adjustment becomes immediately visible to all stakeholders. Managers can approve samples, comment on revisions, or flag issues directly within the system from any location and at any time.

In the Apparel project, Computools implemented a shared digital workspace that enabled merchandisers, designers, and regional managers to collaborate simultaneously. When a product’s fit or material specification changed, notifications were sent in real time, cutting approval cycles from days to hours. This transparency strengthened alignment between departments and ensured that decisions were always based on the latest data, turning collaboration into a measurable operational advantage.

6. Integrate Suppliers and External Partners

True digital transformation in fashion extends across the entire value chain. Fashion supply chain digitalization enables brands to integrate suppliers, factories, and logistics partners into a single, transparent system, enhancing traceability and production agility.

When vendors gain controlled access to the PLM environment, they can upload fabric specs, test results, compliance certificates, and delivery timelines directly into the system. This replaces email chains and scattered spreadsheets with a single, reliable data source for everyone involved.

Looking at the Apparel project, Computools introduced secure supplier workspaces within the client’s platform. Vendors could update material details, quality reports, and certifications directly into the PLM layer, which then synchronized automatically with the retailer’s internal dashboards. This provided the brand with full visibility into supplier performance and material compliance, while reducing communication delays across the global supply chain.

By building this level of connectivity, the retailer not only accelerated sourcing and production but also strengthened sustainability oversight, creating a transparent, efficient, and future-ready supply ecosystem.

7. Leverage Data for Sustainability and Compliance

Modern fashion brands are under growing pressure to prove responsibility at every stage of production. Product lifecycle management for fashion provides tools to track environmental impact, material origin, and compliance directly within the product development process. When sustainability metrics are integrated into daily workflows, ethical design becomes measurable rather than aspirational.

A data-driven PLM system enables teams to calculate carbon footprint, water usage, and recyclability for each item while monitoring supplier certifications and regional regulations. Designers can instantly compare the environmental cost of different materials or production methods, making sustainability an active part of every decision.

In the Apparel case, Computools embedded sustainability tracking modules into the client’s platform, enabling teams to assess emissions, resource consumption, and certification data for each collection in real-time. This visibility enabled the retailer to adjust its sourcing strategies, reduce waste, and maintain full transparency across the supply chain, demonstrating that responsibility and profitability can coexist and grow together.

8. Create Unified Data Flow Across Channels

For fashion retailers operating across multiple online and offline touchpoints, consistency of information is everything. Omnichannel fashion product data management ensures that every product update from new color variants to seasonal pricing is instantly reflected across all sales channels, regions, and digital platforms. This unified data flow eliminates mismatched listings, outdated descriptions, and inventory errors that can lead to lost sales or frustrated customers.

A well-integrated PLM–eCommerce ecosystem allows teams to manage product details once and distribute them automatically to web stores, marketplaces, and POS systems. Centralized control of product information not only enhances operational efficiency but also ensures a consistent brand experience across all channels.

For example, in the Apparel project, Computools implemented automated data synchronization between the client’s PLM system and multiple global marketplaces. When design or material updates occurred, the changes were instantly propagated across all digital storefronts, ensuring that product listings remained accurate and aligned with real inventory. This integration significantly reduced manual data handling and accelerated the rollout of new collections worldwide.

By investing in omnichannel data management, fashion brands can maintain reliability and speed at scale, ensuring that every customer, in every market, sees the same up-to-date product story.

9. Monitor, Train, and Optimize Continuously

Retail digital product information systems require continuous monitoring to ensure data accuracy, user adoption, and long-term scalability. Regular audits of system performance and workflow efficiency help identify bottlenecks early, while proactive updates keep the entire digital ecosystem aligned with new market demands and technologies.

Training is equally essential. Teams across design, merchandising, and eCommerce should receive periodic refreshers to stay up to date with new features and best practices. Continuous learning improves platform adoption and encourages innovation at every level of the organization.

Computools supported the client beyond deployment with regular optimization sprints and user workshops. These sessions helped refine data workflows, improve automation, and ensure that regional teams used the platform consistently. As a result, system reliability improved, and operational speed increased quarter after quarter.

By treating integration as an ongoing process, rather than a one-time project, fashion brands ensure that their connected retail ecosystems remain accurate, flexible, and ready to grow, thereby sustaining both efficiency and creativity over the long term.

Ultimately, fashion PLM integration enables brands to unify creativity and commerce within a single, data-driven ecosystem, facilitating faster launches, consistent product narratives, and informed decisions throughout the entire fashion lifecycle.

Explore how PLM integration brings accuracy and clarity to every product page, fixing the data issues that derail conversions and inflate return rates.

Emerging trends in fashion PLM integration

The landscape of PLM integration is rapidly shifting from traditional back-office systems to intelligent, flexible, and cloud-based platforms that now act as the digital backbone of modern fashion brands. Today’s most significant trends are reshaping how brands design, produce, and bring products to market.

• The integration of AI and Machine Learning into PLM systems enables accurate demand forecasting, smarter material selection, and real-time assortment optimization.

• Cloud-based PLM solutions provide global accessibility, lower infrastructure costs, and seamless scalability, while 3D prototyping and virtual sampling significantly reduce costs and accelerate product development cycles.

• Blockchain-based traceability is gaining traction, ensuring transparency in material sourcing and sustainability compliance.

• Meanwhile, AR/VR collaboration tools enable design and manufacturing teams to work together virtually, creating and reviewing collections without the need for physical samples.

• Modern PLM solutions are moving away from monolithic systems toward API-first architectures, enabling smooth integration with ERP, PIM, DAM, and marketplace platforms. Static tech packs are being replaced by Digital Product Passports, which are dynamic data sets containing material information, certifications, and environmental impact metrics.

For brands ready to future-proof their operations, the following steps are clear: migrate to cloud PLM platforms with open APIs, embed AI/ML and 3D capabilities into product development workflows, launch Digital Product Passports, standardize material and size catalogs, and centralize omnichannel product data.

Setting measurable KPIs such as time-to-market, data accuracy, and return rate reduction ensures that technology investments translate into performance gains.

Ultimately, true transformation arises from integrating PLM with custom eCommerce software development. This integration allows real-time sync of product specs, images, pricing, and availability across online stores, marketplaces, and POS systems. It eliminates data silos and manual updates, providing brands with operational agility, accuracy, and a unified customer experience.

The future of fashion retail is owned by those who recognize PLM as a strategic driver, not just a back-office tool, to enable quicker, smarter, and more sustainable growth.

Global best practices for PLM integration in fashion

In today’s fast-paced retail world, best practices for fashion PLM integration with online stores focus on connecting creativity, data, and commerce into one seamless flow.

Global leaders like Insomnia Visuals and Vivencis Collective illustrate this perfectly. Insomnia reduced development time by 30% through centralized PLM workflows, while Vivencis cut production costs by 20% and increased on-time deliveries by 15% by integrating supply chain and digital retail operations.

Top vendors, including Dassault Systèmes, Lectra, PTC, and Infor, are enabling brands to synchronize product data, automate updates, and ensure transparency through digital product passports. These integrations empower designers, merchandisers, and eCommerce teams to work from a single source of truth, accelerating launches and minimizing costly errors.

Whether it’s Shein leveraging speed, Gucci refining luxury experiences, or Patagonia advancing sustainable transparency, the takeaway is the same: modern fashion success depends on unified PLM and eCommerce ecosystems that merge innovation, precision, and agility across every stage of the product lifecycle.

How Computools delivers scalable PLM and eCommerce solutions

Computools delivers advanced retail software development services that connect PLM and eCommerce into one intelligent ecosystem. Our engineers design integration layers that synchronize product data, design assets, and inventory across PLM, ERP, marketplaces, and POS systems, thereby eliminating the need for manual updates and data silos.

In projects like Apparel, we helped a global fashion retailer unify its PLM platform with digital sales channels, creating real-time visibility from design to delivery. The result was faster approvals, fewer errors, and seamless collaboration between designers, merchandisers, and suppliers. By integrating scalable architecture with automated workflows and live analytics, Computools ensures every retail platform adapts smoothly to growth and market demand, transforming complex operations into measurable business performance.

Ready to connect your PLM and eCommerce systems? Contact our retail experts at info@computools.com to discuss your next transformation project.

Computools

Software Solutions

Computools is a digital consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”