In retail, even minor errors in inventory data can translate into millions in losses. Lack of real time inventory retail visibility leads to overstocks, shortages, and supply disruptions, directly impacting profitability. Up to 60% of retail inventory records are inaccurate, causing over $400 billion in annual losses due to miscounting and unavailable items.

McKinsey notes that most stores have an inventory accuracy rate of only 70–90%, meaning that one in ten items is incorrectly displayed in the system. Such inaccuracies create “empty shelves” for shoppers while inventory remains in the warehouse.

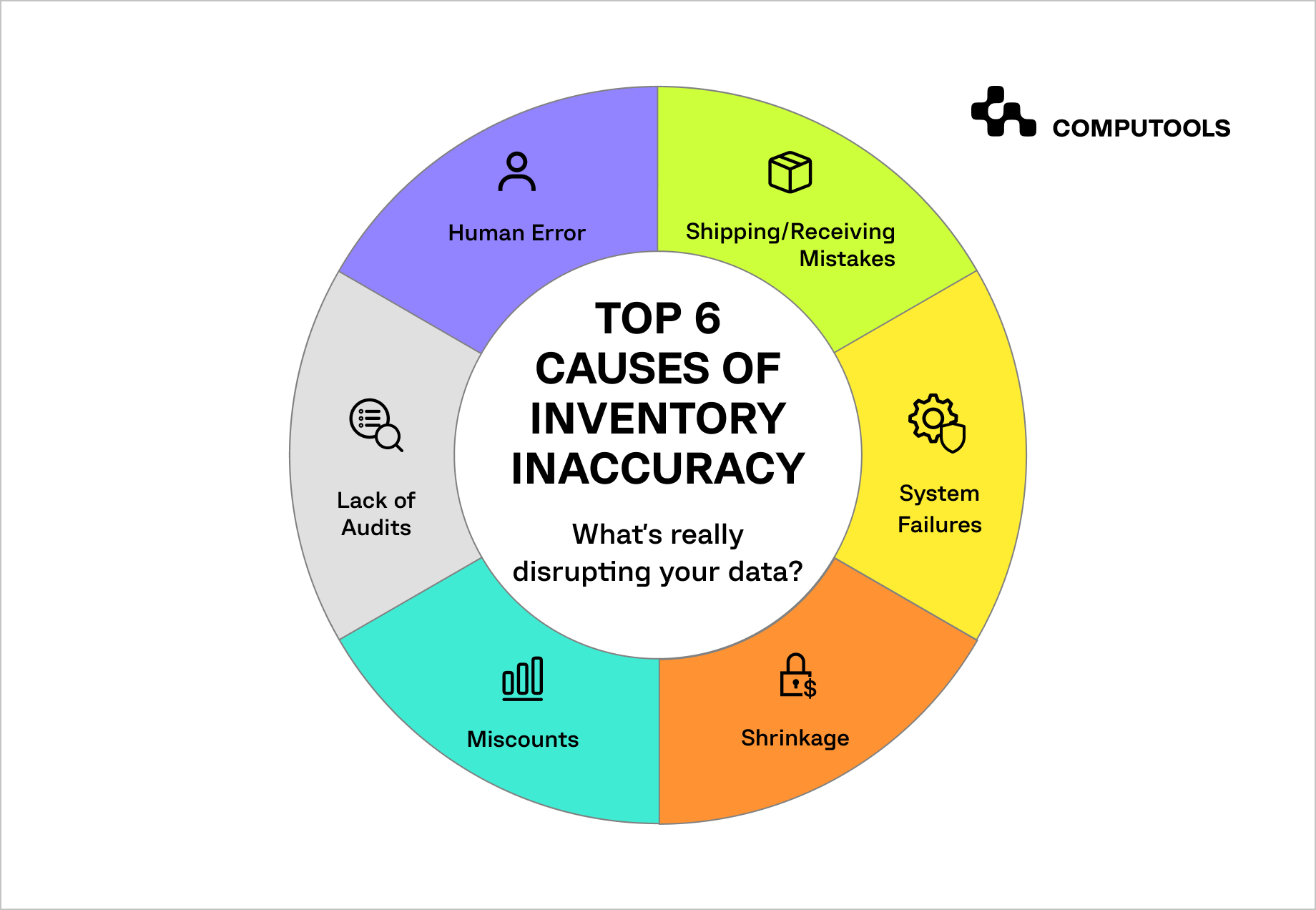

These numbers reveal only part of the challenge. Inaccurate inventory data often stems from several recurring operational issues that can disrupt retail performance:

Each of these factors contributes to fragmented data and delayed decision-making. Solving them requires process control and a technological framework capable of real-time visibility, the foundation for any modern inventory system.

At Computools, we advocate for real time inventory retail solutions using RFID and IoT that deliver complete transparency and control across every stage of the supply chain. By combining RFID tags, IoT sensors, and cloud analytics, retailers can monitor stock movement, product conditions, and expiry dates in real time, bridging the gap between online and in-store operations.

These IoT software solutions eliminate data silos, automate inventory updates, and enable predictive replenishment, ensuring that every product is available at the right location and time. The outcome is higher inventory accuracy, lower operational costs, and a smoother customer shopping experience.

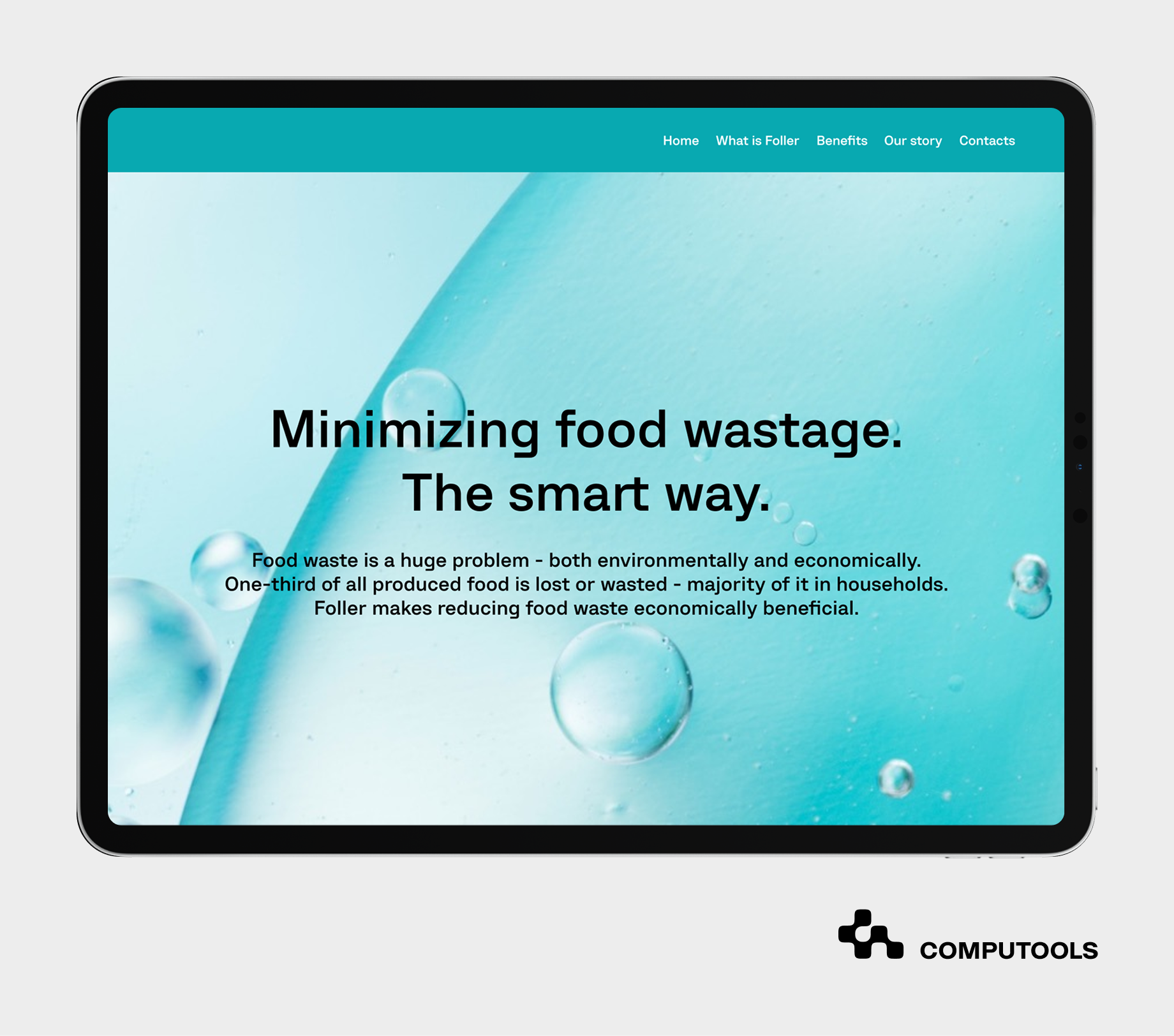

A clear example of this approach is the E-Feller platform, developed by Computools for a Finnish startup aiming to reduce food waste through smart inventory visibility. Using IoT devices to track product flow and shelf life, the platform combined RFID tags, IoT sensors, GPS trackers, and barcode scanning to ensure end-to-end visibility from manufacturer to retail shelves. The solution enabled first-in, first-out (FIFO) rotation and predictive analytics for replenishment.

As a result, E-Feller achieved a 75% reduction in food waste across the supply chain, building a scalable, sustainable retail model.

How Computools enabled real-time inventory visibility across online and in-store operations using RFID/IoT

As part of our retail software development services, Computools helped E-Feller solve the challenge of fragmented and inaccurate stock data by designing a unified IoT-based system for real time inventory retail operations. The goal was to connect manufacturers, distributors, and retail stores through an intelligent platform capable of tracking every product’s location, condition, and expiry date in real time.

Our engineers developed a scalable reference design that integrates RFID tags, IoT sensors, GPS tracking, barcode recognition, and cloud analytics to deliver real-time inventory visibility across online + stores using RFID/IoT. The solution automatically synchronizes data across the supply chain, predicts stock shortages, and recommends optimal product rotation to reduce waste and operational costs.

For E-Feller, this platform resulted in a 75% decrease in food waste, improved logistics efficiency, and lower carbon emissions, demonstrating how connected, data-driven retail ecosystems can enhance transparency, sustainability, and business performance.

We share this case because Computools has experience helping retailers integrate connected systems and achieve real-time visibility. Our expertise in IoT and retail software enables us to create solutions that promote transparency, efficiency, and sustainability.

How to achieve real-time inventory visibility across online and in-store operations using RFID/IoT (reference design)

Creating real time inventory visibility means transforming fragmented retail data into a continuous, transparent flow that reflects every product’s location, condition, and availability in real time. Below is a practical framework demonstrating how retailers can achieve this, supported by Computools’ experience with the E-Feller project.

Step 1. Map and Integrate the Inventory Ecosystem

The foundation of any real-time inventory visibility initiative is understanding how data flows through the retail ecosystem. Before any sensors or automation are added, retailers must identify where information is generated, delayed, or lost. In most cases, discrepancies appear because inventory records are updated manually, reports are delayed, or critical systems like ERP, POS, and warehouse software remain disconnected.

To eliminate these gaps, the first step is to map the complete data journey from supplier input and warehouse receipts to store-level transactions and online sales. Each checkpoint should be connected to a unified system automatically updating data in real time. This integration builds the “digital backbone” for all subsequent automation and monitoring layers.

Computools applied this approach while developing the E-Feller platform. The project started with analyzing data flows among manufacturers, distributors, and retailers, uncovering isolated processes hampering accurate stock updates.

We developed APIs and automation scripts to unify systems into a single data loop. Consequently, product movements, temperature, and expiry dates became instantly visible across the network, enabling reliable IoT tracking and optimization.

Step 2. Deploy RFID and IoT Devices

After mapping data flows, the next stage is building the physical and digital foundation that supports automated tracking. Implementing RFID IoT inventory management technologies allows retailers to replace manual data entry with constant, sensor-based monitoring.

RFID (Radio Frequency Identification) tags contain microchips that store unique product data from serial numbers and batch codes to expiry dates and supplier details. These tags communicate with antennas and readers through radio waves, allowing hundreds of items to be scanned at once, without direct line-of-sight. This bulk reading capability differentiates RFID from traditional barcodes and gives retailers instant, highly accurate stock counts.

Meanwhile, IoT sensors extend visibility beyond identification. They record environmental factors such as temperature, humidity, vibration, or location and send this data through gateways to the cloud. With RFID readers, IoT devices form a connected network that continuously updates the inventory system in real time.

Computools applied this approach while developing E-Feller’s food supply chain platform. Each container and product package received an RFID label with embedded expiry data, while IoT sensors monitored temperature, humidity, and movement along transport routes. GPS trackers and barcode scanning were added to verify product locations in transit and at retail checkpoints. All readings were transmitted through secure gateways to a central analytics platform that automatically updated stock levels and shelf-life information.

This combination of RFID, IoT, and GPS technologies replaced periodic manual checks with uninterrupted, sensor-driven monitoring. The result was full transparency of inventory conditions, reduced spoilage, and faster decision-making across warehouses, delivery routes, and retail points.

Step 3. Build a Smart Inventory Tracking System

Once RFID and IoT devices are deployed, the next step is to create a smart inventory tracking system, the central layer that transforms raw sensor data into actionable insights. This platform serves as the operational “brain,” consolidating inputs from scanners and sensors, processing them in real time, and synchronizing updates across retail, warehouse, and online systems.

A robust system should include:

• Real-time data processing: continuous data ingestion from IoT gateways, duplicate filtering, data validation, and matching with product master records (SKU, batch, expiry date, location).

• Digital twin of inventory: a live, unified model representing every item’s quantity, location, condition, and lifecycle stage (in transit, on shelf, reserved, or nearing expiry).

• Rules and automation: triggers for shelf replenishment, first-expiring-first-out (FEFO) product rotation, or alerts when temperature limits are exceeded.

• Analytics and dashboards: real-time visualization of stock flow, out-of-stock risks, inventory turnover, and performance KPIs.

• API layer: integration with ERP, POS, and eCommerce systems to ensure every inventory update is instantly reflected across all channels.

Computools implemented this architecture while building the E-Feller platform. After connecting RFID tags and IoT sensors, we designed a data pipeline that collected and validated sensor events, linked them with product metadata, and automatically updated each item’s digital twin.

The platform applied business rules to prioritize rotation, generate staff tasks, and synchronize product data with partner systems. As a result, E-Feller achieved uninterrupted visibility of inventory conditions, real-time expiry tracking, and faster operational response with minimal manual effort.

Step 4. Enable Real-Time Monitoring for Retail Operations

With the smart tracking layer established, the next goal is real time monitoring for retail, turning continuous data streams into operational awareness. Real-time monitoring ensures that store and warehouse teams always have an accurate view of stock levels, product health, and order flow, allowing proactive rather than reactive decisions.

Effective monitoring combines three components:

• Sensor-driven updates: data from RFID and IoT devices provides live feedback on item movement, replenishment needs, and temperature deviations.

• Automated alerts: the system generates instant notifications for low inventory, delayed shipments, or approaching expiry dates, helping staff take corrective action immediately.

• Predictive analytics: algorithms analyze historical data to anticipate stockouts, optimize delivery routes, and balance distribution between stores and online channels.

In the E-Feller project, Computools implemented real-time dashboards that visualized product flow and shelf-life metrics. When sensors detected temperature fluctuations or when items approached expiration, the system triggered automatic alerts and suggested redistribution to high-demand areas.

This continuous monitoring process minimized waste, improved delivery accuracy, and created a self-regulating retail network capable of responding instantly to operational changes.

Step 5. Integrate IoT Inventory Visibility Solutions with Cloud Infrastructure

Achieving real-time visibility across a distributed retail network depends on reliable, scalable cloud connectivity. Integrating IoT inventory visibility solutions with cloud infrastructure ensures that every data point from shelf sensors to delivery trucks is instantly accessible, processed, and analyzed within a unified environment.

In this stage, all sensor and RFID data streams converge in the cloud, where information is cleaned, validated, and made available to analytics dashboards and decision engines. Cloud-based storage eliminates the limitations of on-premise systems, allowing retailers to expand effortlessly across locations while maintaining consistent visibility.

A well-architected cloud setup enables:

• Continuous data synchronization between warehouses, stores, and online systems.

• Scalability, allowing new sensors, devices, or product categories to be added without downtime.

• Integration with ERP and CRM systems to align operational data with customer and financial insights.

• Security, ensuring that sensitive retail and supplier data is encrypted and protected across endpoints.

Computools built a hybrid cloud IT infrastructure using secure gateways to collect data from IoT devices and RFID readers in the E-Feller platform. The cloud layer handled millions of daily transactions, giving partners instant access to product conditions, expiry dates, and history. This centralized system replaced siloed reports with real-time analytics, supporting data-driven decisions from production to delivery.

Step 6. Apply RFID Retail Technology for Automation

Once data is centralized, automation becomes the key to speed and accuracy. RFID retail technology transforms manual stock operations into automatic workflows by removing the need for physical scanning or data entry. Every time an item passes through an RFID checkpoint at receiving docks, warehouse exits, or store shelves, its information is updated automatically in the system.

Automation benefits include:

• Faster inventory counts: hundreds of items scanned simultaneously instead of one by one.

• Reduced human error: automated updates ensure precise stock visibility.

• Labor cost savings: fewer manual checks and shorter audit cycles.

• Enhanced customer experience: accurate real-time stock data eliminates “phantom inventory” online.

In E-Feller’s implementation, automated RFID scanning replaced manual reconciliation across storage and retail checkpoints. When tagged goods entered or left a location, the system updated inventory levels and triggered automated workflows like alerting staff to replenish shelves or reroute products nearing expiry.

This automation reduced administrative load, cut processing time, and ensured constant physical and digital stock alignment.

Step 7. Achieve Omnichannel Inventory Management

For retailers operating across multiple sales channels, visibility must extend beyond individual systems. Omnichannel inventory management unifies online and offline data, ensuring consistent product availability across websites, warehouses, and stores. Customers expect seamless experiences ordering online, picking up in-store, or returning to another branch, and that’s only possible when all systems share the same live inventory feed.

Key components include:

• Unified data model: one database feeding both online and offline interfaces.

• Channel synchronization: every sale, return, or transfer updates the global stock count.

• Order routing intelligence: the system automatically determines the optimal fulfillment point (nearest store, central warehouse, or partner facility).

During the E-Feller project, Computools implemented an integrated data model linking suppliers, distributors, and retail outlets in real time. When a product’s status changed in one node, it was instantly updated everywhere. This synchronization optimized inventory use across locations, supported more flexible customer fulfillment strategies, and reduced delivery time.

Step 8. Implement Real-Time Retail Data Synchronization

A successful system relies on real time retail data synchronization and constant communication between devices, applications, and analytics engines. Synchronization ensures that every transaction (sale, shipment, or return) immediately updates across all systems, maintaining one version of the truth for inventory data.

In E-Feller, Computools deployed real-time synchronization protocols to connect RFID gateways, IoT sensors, and cloud databases. When an item was scanned or a condition changed, the update propagated through all dashboards from logistics to retail analytics, ensuring zero data lag. This consistency prevented duplicate records and allowed instant cross-team decisions, from restocking to dynamic pricing.

Step 9. Connect the Retail Network into One System

All inventory-related processes must converge into one cohesive ecosystem to maximize efficiency and transparency. Connected retail inventory systems unify warehouses, stores, suppliers, logistics partners, and eCommerce platforms within a shared digital environment. This eliminates silos; every participant works with the same live data, enabling end-to-end visibility and coordination.

The backbone of such connectivity is a secure data exchange framework that integrates multiple systems through APIs and middleware. It ensures that updates in one node (for example, a new shipment arrival or an online purchase) are reflected instantly across the entire retail chain. This level of synchronization supports collaborative planning, faster order fulfillment, and reduced operational friction.

In practice, Computools built this connected infrastructure for E-Feller by linking manufacturers, distributors, and retailers into one unified network. The system aggregated data from IoT sensors, RFID readers, and partner databases into a single cloud platform, accessible to all stakeholders. This transparency improved collaboration, streamlined communication, and gave every participant a reliable view of inventory movement and product conditions.

The result was a supply ecosystem operated as one synchronized network rather than a chain of isolated entities.

Step 10. Enhance Analytics with Inventory Tracking Using IoT Sensors

The final step in achieving long-term efficiency is transforming real-time data into predictive intelligence. Retailers can move from simple monitoring to advanced forecasting and optimization by using inventory tracking with IoT sensors. IoT sensors continuously capture data about temperature, humidity, movement, and shelf-life indicators. Combined with machine learning models, this data helps predict demand, detect anomalies, and optimize stock distribution before issues occur.

Core capabilities of this stage include:

• Predictive analytics: using historical and live data to anticipate stock shortages or surpluses.

• Automated decision support: triggering replenishment, reallocation, or promotional discounts based on real-time insights.

• Quality control: detecting environmental deviations early to prevent spoilage or non-compliance.

• Sustainability metrics: tracking waste reduction, carbon footprint, and product lifespan improvements.

Computools developed analytical modules in the E-Feller platform that combined IoT sensor data with cloud-based AI algorithms. The system forecasted product demand and shelf-life trends, automatically adjusting logistics routes and recommending which items should be shipped or used first. This predictive layer transformed E-Feller’s platform from a monitoring tool into a self-optimizing network, reducing food waste by 75 % while maintaining supply chain efficiency.

Through these ten steps, Computools demonstrated how IoT and RFID technology for real time retail inventory tracking can transform fragmented retail operations into an intelligent, self-learning ecosystem. By connecting physical assets with digital data flows, retailers gain end-to-end transparency from production and warehousing to shelf management and online synchronization.

Learn how to scale a fashion retail platform for high traffic and seasonal peaks, from performance optimization to seamless customer experience.

Learn how to unify store shelves, backroom stock, and online availability with a scalable RFID/IoT reference model.

Global best practices in real time inventory retail

Around the world, leading companies are proving that automation and connectivity redefine retail efficiency. Real-time inventory management powered by RFID and IoT enables full transparency across stores and supply chains, helping brands maintain precision, speed, and sustainability.

1. Amazon Go – Real-Time Retail Without Checkouts

Amazon Go pioneered retail automation using RFID and IoT, creating a fully self-service shopping model. Every item carries an RFID tag, while IoT sensors and cameras track product movement throughout the store. The system automatically updates their virtual carts and stock levels as customers take or return products.

This constant synchronization removes manual input and allows managers to monitor inventory accuracy, product flow, and replenishment in real time, proving that seamless automation can also elevate customer experience.

2. DHL Supply Chain – Smart Warehouses and Data Visibility

DHL transformed its global operations through IoT-based inventory control systems integrated with SAP EWM. RFID tags on pallets and IoT sensors in storage areas provide real-time tracking of shipments, location, and environmental conditions.

This setup established real time supply chain visibility, allowing DHL to track goods across multiple warehouses and transit points simultaneously. The automation reduced manual scanning, improved fulfillment speed, and strengthened sustainability through energy optimization.

3. BASF – Sensor-Driven Chemical Inventory Management

In BASF’s chemical warehouses, IoT sensors monitor product levels and environmental factors such as humidity and temperature. The data is processed in real time and synchronized with supply management systems. Automated alerts ensure compliance and safety, while analytics reduce overstock and optimize replenishment cycles.

BASF achieved store and online inventory integration by integrating warehouse and distribution analytics, ensuring that production and retail channels operate with consistent, synchronized data.

4. Siemens – Predictive Analytics in Industrial Warehousing

To enhance visibility and forecasting, Siemens integrated sensors and RFID-enabled tracking across its logistics hubs. Real-time data on item movement, bin occupancy, and vibration patterns feeds predictive models that anticipate shortages or misplacements before they occur. This initiative strengthened real time inventory retail performance by transforming static warehouses into dynamic, data-driven environments where materials, products, and digital systems operate as one coordinated network.

Global leaders like Amazon, DHL, BASF, and Siemens demonstrate that digital transformation in retail is not limited to scale but to vision. Real-time visibility powered by RFID and IoT delivers measurable accuracy, operational efficiency, and resilience, shaping the next era of intelligent retail management.

If you want to optimize your retail operations with connected systems and data-driven efficiency, explore the Top 20 IoT Software Development Companies for Retail Supply Chains leaders in transforming logistics and inventory management through smart IoT solutions.

Why choose Computools

At Computools, we help retailers bring these innovations to life through tailored IoT development services that connect every stage of the supply chain, from warehouse sensors to smart store analytics. With experience across 20+ retail projects, our teams have built platforms that track real-time product flow, integrate online and in-store systems, and reduce operational waste through automation and predictive analytics.

Our expertise extends beyond technology to strategic implementation: designing scalable, secure, and data-driven ecosystems for retail and FMCG clients worldwide. Whether you need end-to-end visibility or custom grocery retail software development, Computools provides the engineering foundation and domain experience to turn real-time insights into measurable business results.

If you’re exploring how to implement real-time visibility or automate your retail operations, our experts are ready to help. Write to us at info@computools.com, let’s discuss how technology, data, and strategy can work together to drive your next retail transformation.

Computools

Software Solutions

Computools is a digital consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”