There is no doubt that digital transformation profoundly impacts every aspect of the business world, spanning industries and global manufacturing processes. It propels product development to new heights, reduces production costs and ensures customer satisfaction.

Nonetheless, this transformation presents both opportunities and challenges, including workforce adaptation, environmental regulations and other concerns accompanying broader possibilities.

In collaboration with Bill Holler, founder and CEO of TraCert OÜ, a respected figure in the aerospace sector and standardisation, Computools has created an article covering important aspects of digitalisation in the industry.

About Bill: Throughout his career, Bill Holler has held leadership positions in both the aerospace and fastener industries.

Serving as the elected Chairman of DIN NL – the German Institute for Aerospace Standardisation – Bill plays a key role in bolstering the global recognition of European aerospace standards.

Drawing upon his extensive experience as an aerospace business consultant, he now heads TraCert OÜ, a prominent Estonian technology company providing solutions for the blockchain-secured digitalisation of essential documents.

Additionally, contributing to this article was the CTO of TraCert OÜ, Max-Ole Casdorff, who brings more than a decade of experience in project management and has deep expertise in the technical aspects of digital transformation.

Aerospace Industry Overview

The aerospace industry is a giant global sector that involves designing, making and maintaining aircraft, spacecraft and related systems.

It covers commercial and military areas, including space exploration, with key players like aerospace manufacturers, defence contractors and space agencies.

While there was a significant drop in aircraft orders during the COVID-19 pandemic, the aircraft manufacturing sector is now recovering.

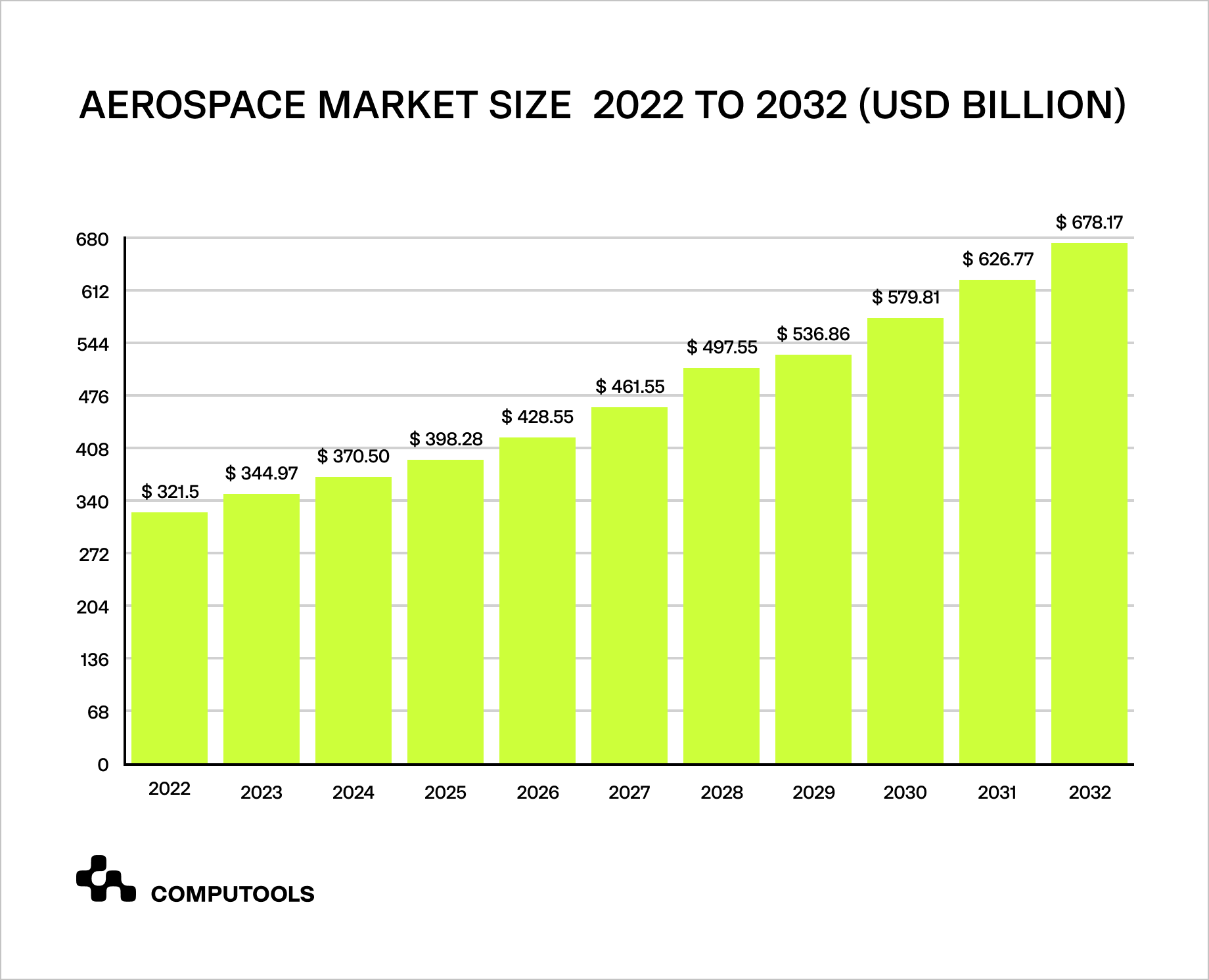

It’s projected that the global aerospace market will reach approximately US$678.17 billion by 2032, growing at a rate of 7.80% annually from 2024 to 2032.

The aerospace industry is mostly dominated by major players in North America and Europe. In North America, companies like Boeing and Lockheed Martin lead in both commercial and military aviation.

Similarly, Europe is at the forefront of technology and innovation, with giants such as Airbus and Rolls-Royce. Both regions not only cater to a strong demand for commercial and military aircraft but are also pioneers in sustainable aviation practices.

One of the primary drivers of the aerospace market is the expansion of commercial aviation. To meet the rising passenger demand, airlines are enlarging their fleets, which in turn encourages aircraft manufacturers to innovate more fuel-efficient and environmentally friendly planes.

Furthermore, the industry is significantly supported by increasing global defence and security needs, with about 20% of its sales attributed to the defence sector.

As governments worldwide seek to enhance their military capabilities, there is a surge in demand for aerospace companies to supply advanced equipment and technology.

This dual focus on commercial growth and defence needs, alongside a commitment to sustainability, underpins the dynamic evolution of the aerospace industry.

Climate Neutrality Goals: A Key Driver of Digital Transformation

Currently, stakeholders across all industries – including investors, regulators and consumers – are pushing for the integration of ESG (environmental, social and governance) principles and sustainability into everyday operations.

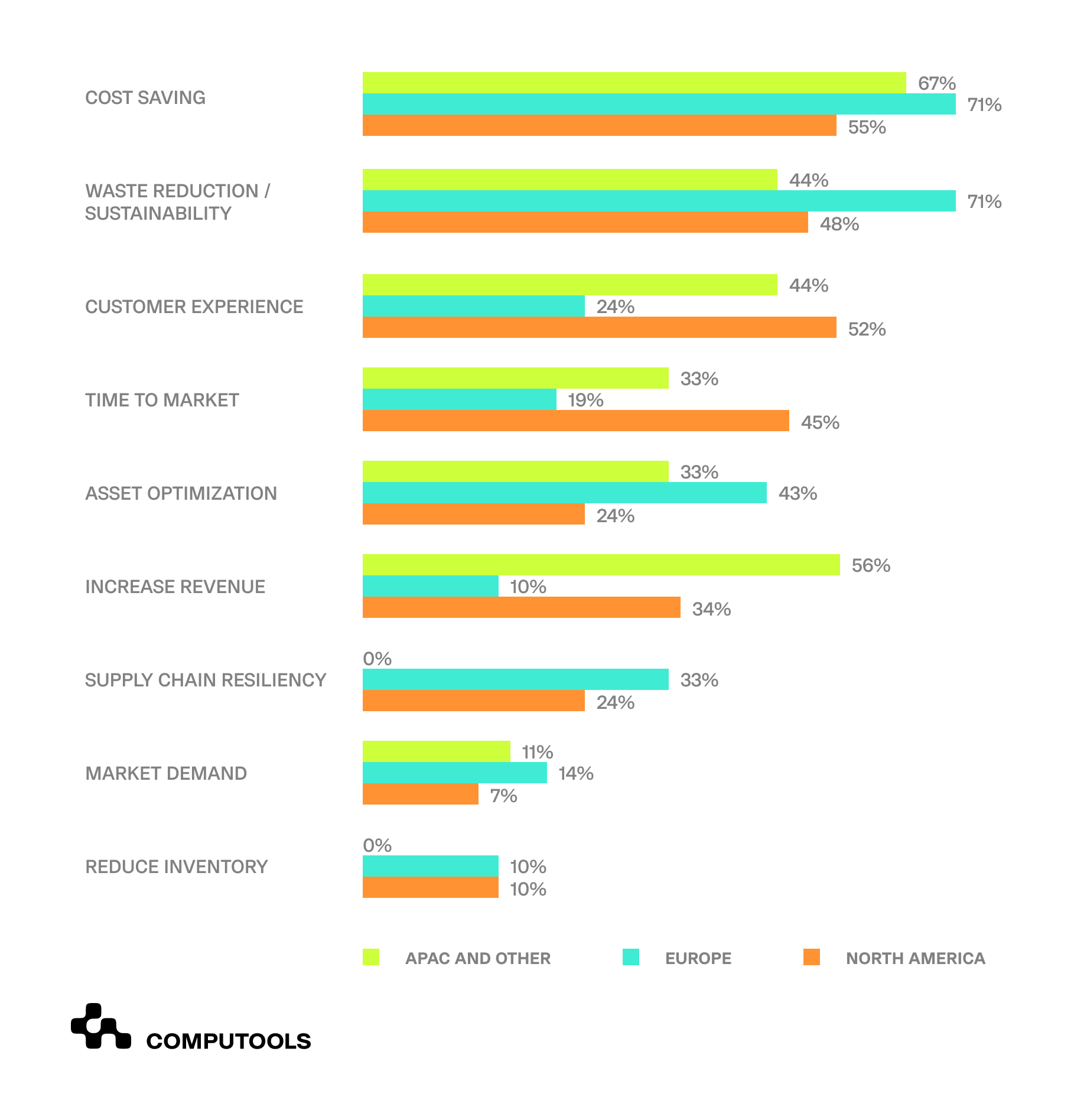

According to the ISG Smart Manufacturing Survey, achieving sustainability is a critical objective for manufacturers within the Global 2000.

While governments are making strides towards sustainability objectives, Bill Holler suggests their influence in effecting change is not as significant as it could be. He explains:

‘The aerospace industry has committed to becoming carbon neutral, partly due to public pressure and the need to avoid negative impacts on the market. Although governments may not be playing a significant role in driving this initiative, we can see that the industry itself is leading the way in this development.’

Bill also regards the pursuit of climate neutrality as the primary driver for digital transformation within the industry, stating:

‘The aerospace industry is inherently complex, with highly sensitive processes such as production, development and testing. The need to use the best available tools has never been more critical. This commitment to achieve carbon neutrality goes beyond materials and requires innovation in aircraft designs, engines and technologies with this goal in mind.’

He believes that relying solely on traditional methods will not enable the industry to meet these ambitious environmental objectives. In the past, developments have spanned decades, but there is no longer the luxury of time.

Additionally, the expert emphasises the clear need for an industry traditionally focused on physical aspects, like aerodynamics and design, to collaborate and leverage the expertise and skills of other companies.

This collaboration is important for realising the industry’s goal of fully embracing digital advancements in the future.

Emerging Technologies in Aerospace

Bill Holler has highlighted several key technologies that he considers the most important in driving digital transformation within the aerospace industry and meeting stakeholder needs:

1. Blockchain

‘Blockchain is indeed an important technology for securing the integrity of documentation,’ Bill explains. ‘That’s why TraCert has developed an exceptionally secure archiving system protected by blockchain technology. In our approach, it’s a green blockchain technology, noted for its energy efficiency.’

2. Artificial Intelligence

The expert expresses both enthusiasm and caution regarding AI.

‘You cannot look into AI brains,’ he notes, emphasising the industry’s need for transparency in decision-making.

Despite these concerns, Bill acknowledges the transformative potential of AI in automating labour-intensive tasks.

3. Digital Thread

The digital thread concept enables agile practices and speeds up product development in the aerospace industry. This strategy ensures seamless data exchange across the supply chain, creating an integrated design ecosystem that tackles complex challenges and modernises traditional engineering workflows.

4. Robotics

Robotics are increasingly boosting accuracy and efficiency in various aerospace applications. They’re used for assembling aircraft components with unmatched precision and performing inspections and maintenance tasks.

Our experts expect robotics to expand further in the future, with drones likely to take on more complex tasks like remote inspections and cargo delivery.

5. Internet of Things (IoT)

The experts also emphasise the growing significance of IoT in enhancing operational efficiency and safety. IoT sensors and devices enable real-time equipment monitoring, essential for proactive maintenance and issue resolution.

Furthermore, IoT technologies allow airlines to provide personalised experiences, from live flight updates to tailored in-flight services.

Challenges in Digital Transformation

Today, leading aerospace companies are increasingly investing in technologies that incorporate cloud computing, AI and the IoT, adopting a digital thread manufacturing strategy.

However, the adoption of these advanced technologies also introduces some challenges.

1. Data Storing

Aerospace companies are grappling with the challenge of managing and storing the vast quantities of data they generate, including product design data, manufacturing process data, updates on supply chain data, IoT data from products in the field, and customer and client feedback data.

To address this challenge, Bill highlighted the significance of blockchain technology:

‘With our powerful archiving tool, Cert-Trace, we can store millions of documents related to quality inspections, their protocols and so on. Looking ahead, with the assistance of artificial intelligence, these digital documents can be analysed even more effectively. This process transforms what we might call a “data graveyard” into “data soil”, where valuable data can be cultivated from our comprehensive digital archives.’

2. Resistance to change

Bill Holler points out that the primary obstacle in digital transformation is often the resistance to change. He shares a compelling example from his career.

‘When I started about 20 years ago as the Chairman of the board of the German Standardisation Organisation, the experts there were following practices that hadn’t changed in decades. Any attempt at introducing new methods was met with resistance. However, persistence paid off. Over time, we welcomed new experts eager for innovation, allowing us to implement cutting-edge standards across the aerospace industry. Changing people’s mindsets is a key task, often about bringing in fresh perspectives rather than convincing everyone to adapt.’

CTO of TraCert OÜ Max-Ole Casdorff further elaborates, ‘Resistance to change is a constant. However, once people are on board with change, there emerges a fundamental misunderstanding of what digitalisation means. Many assume it’s merely about converting existing processes and documents into digital formats, missing the broader opportunity to fundamentally redesign processes. True digital transformation requires rethinking and reinventing processes from the ground up.’

3. Cybersecurity Concerns

As digital activities increase, cybersecurity becomes more critical, especially for companies working with federal agencies.

Adhering to the stringent standards required for compliance with the Cybersecurity Maturity Model Certification (CMMC) is becoming increasingly important.

Max-Ole Casdorff emphasises the key role of cybersecurity, stating, ‘Cybersecurity needs to be a priority in all activities, not merely a secondary concern. It must be an integral part of the system’s architecture. This principle requires clear communication because as systems become more complex, cybersecurity challenges also increase. It’s really important to demonstrate this commitment to cybersecurity to clients and end-users to preserve their trust in the systems.’

Furthermore, he notes that although advancing technology brings higher risks, humanity has not refrained from exploring new opportunities despite potential dangers.

’Historically, we have adapted and learned to navigate these risks, and I am confident that we will continue to do so in the digital realm,’ – he says.

Education and Skills for the Digital Era

Like many industries today, the aerospace sector is grappling with challenges related to talent shortages, retaining aerospace engineers, managing turnover and sustaining workforce capacity.

According to the Bureau of Labor Statistics, the United States will need 3,800 new aerospace engineers every year until 2031.

This situation prompts an important question: How is digital transformation influencing the skill requirements in the industry?

Bill comments, ‘Historically, acquiring specific skills through education was crucial for performing well in a job. Yet, in the changing environment of today, having less specialised education might be more beneficial for the future. The most valuable skills now are the ability to adapt mentally and the readiness to replace old methods with new, necessary ones. Considering that many future job roles do not yet exist, it’s challenging to prepare for them specifically.’

Max contributes, ‘At TraCert OÜ, our goal is to minimise the impact of change on employees’ daily tasks worldwide. Thanks to the digital age, interfaces can be made much more user-friendly, enhancing our natural workflows rather than confining us to inflexible document formats. Although a fundamental understanding of computers and software is required, comprehensive technical knowledge is less necessary, simplifying the process of becoming proficient.’

The experts agree that adaptability and a passion for innovation have become more important than traditional educational qualifications. With the rise of AI, the way people interact with technology is fundamentally shifting.

Predictions for the Near Future

Predicting the future in such uncertain times is challenging, but here are some expert insights on emerging technologies poised to further drive digital transformation in the industry.

1. Intelligent Documentation

Bill highlights the growing significance of intelligent documentation.

He explains, ‘This involves using digital formats, like digital standards and XML, to transition from old-school paper documents to interactive, digital ones. This shift is set to make a big impact on the aerospace industry, beginning immediately and continuing over the next years.’

2. Digital Twin Technology

Bill also forecasts the continued evolution of digital twin technology. When integrated with other Industry 4.0 technologies, it enables aerospace engineers to run simulations on virtual replicas of aeroplanes or spacecraft.

This technology enhances productivity, reduces risk, improves product quality and shortens production timelines.

3. Quantum Computing

‘The potential of quantum computing, which is on the horizon, should not be overlooked,’ Bill asserts.

He points out that a critical aspect of aircraft development involves testing in wind tunnels, engine performance assessments and ultimately, flight testing – activities that are predominantly manual as of 2024.

However, the advent of quantum computing is set to revolutionise these processes through simulation, marking a significant leap towards achieving carbon or climate-neutral aviation by 2050.

Summing Up

To conclude this article, we quote Bill Holler’s advice to entrepreneurs considering digital transformation initiatives: ‘Start now. Don’t waste another day. Be optimistic about the best while preparing for the worst.’

The Computools team extends our thanks to Bill Holler and Max-Ole Casdorff for their contributions of knowledge. We hope that aerospace professionals will find useful insights within this article to aid them in maintaining growth and achieving success.

Want to implement modern solutions in your aerospace operations? Contact us today at info@computools.com to learn how we can help propel your business forward.

Computools

Software Solutions

Computools is an IT consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”