Logistics today resembles a living organism, with IoT acting as its nervous system, fast, sensitive, and omnipresent. Just a few years ago, the IoT market in this sector was valued at $44 billion, and by 2031, it may nearly triple, surpassing $125 billion.

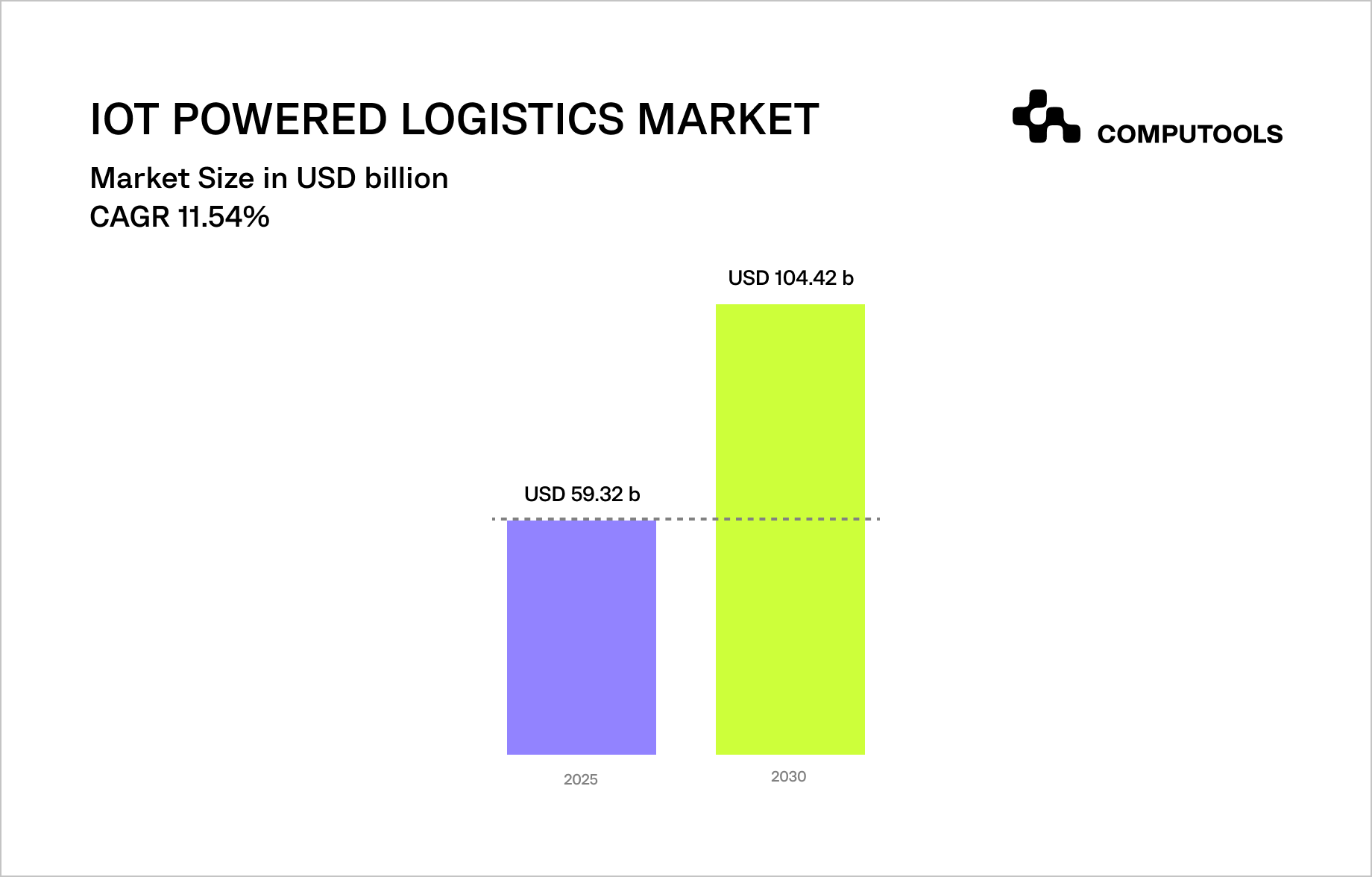

These are not just dry numbers: they reflect how transport companies worldwide rapidly shift from “blind” routes to complete transparency in movement. Analysts at Mordor Intelligence confirm this trend: according to their report, by 2025, IoT-powered logistics will approach $60 billion and exceed $100 billion by 2030.

This surge is equally visible in IoT in fleet management. In 2024, the market for these solutions was valued at $9 billion; by 2034, it is projected to exceed $26 billion.

More than 80% of large fleets in North America already rely on real-time tracking systems for fleet logistics optimization, while in Australia and New Zealand, the adoption rate is close to three-quarters.

The benefits are clear: companies report 42% fewer safety incidents, 55% savings on fuel, and a measurable ROI in over 60% of cases.

This is reinforced by the explosive growth of LPWAN networks, which enable monitoring of cargo details like temperature, pharmaceutical containers, and food humidity delivery. The forecast is estimated at 48.7 billion USD in 2025, and increased to 395.6 billion USD by 2030 at a CAGR of ≈52%.

We are already living in an era where seeing cargo in real time is no longer a luxury but a standard. Route optimization with IoT software transforms fleet operations into a dynamic, predictable system that forms the backbone of future logistics.

What is IoT in fleet management, and how does it work?

At its core, the Internet of Things (IoT) refers to networks of physical assets that collect and exchange data. These “things” can be vehicles, containers, pallets, or individual packages in logistics.

Equipped with smart sensors, RFID tags, and GPS trackers, they constantly transmit updates on location, condition, and performance. This connectivity forms the backbone of IoT for fleet management, where every vehicle becomes part of an intelligent ecosystem.

Key technologies driving IoT in logistics

• Smart sensors monitor engine health, tire pressure, temperature, humidity, and cargo stability.

• RFID tags and smart labels automate asset identification and inventory tracking.

• GPS trackers provide continuous real-time tracking and geofencing.

• Telematics systems aggregate sensor data to reveal driver behavior and vehicle performance insights.

• Cloud platforms consolidate information across the supply chain into dashboards for faster, more informed decision-making.

These tools replace manual checks and paper logs, helping teams work faster, avoid errors, and respond immediately when something goes off track.

IoT applications in fleet management

The use of IoT in fleet operations goes far beyond GPS. Integrated fleet tracking systems enhance transparency, safety, and cost efficiency through a variety of applications:

• Battery life monitoring with alerts when IoT devices run low.

• Driver behavior analysis to identify harsh braking, speeding, or idling.

• Unauthorized use alerts when vehicles operate outside approved times or locations.

• Predictive maintenance reminders to reduce downtime and extend vehicle lifespan.

• Downtime and asset utilization reporting, optimizing fleet capacity.

• Integrated reporting for complete visibility and analytics-driven decisions.

• API integration with ERP, CRM, or HRM platforms to ensure smooth data flow.

• Fuel consumption monitoring for cost control and sustainability.

• Route optimization using live traffic data and predictive analytics.

• Driver communication platforms for direct updates between dispatchers and drivers.

• Emergency alerts in case of accidents or mechanical failures.

• Multi-user access so managers, drivers, and maintenance crews have role-specific dashboards.

These use cases show IoT logistics solutions deliver measurable ROI by cutting costs, improving safety, and streamlining operations.

Main elements of the IoT fleet ecosystem

1. Vehicle & environment sensors

Smart sensors form the foundation of IoT asset tracking, capturing GPS location, cargo temperature, tire pressure, engine health, and driver actions. They enable companies to monitor vehicles and goods across the supply chain in real time.

2. Telematics gateway

This in-vehicle hub aggregates, preprocesses, and encrypts sensor data. Modern telematics in logistics ensures that insights on performance, fuel use, and safety reach managers securely and without delay.

3. Connectivity layer

The network backbone moves real-time data via 4G/5G, LPWAN, satellite, Wi-Fi, or Bluetooth. It powers connected tracking systems for logistics and transportation, making it possible to follow shipments globally with seamless visibility.

4. IoT & data platform

Cloud-based platforms manage connected devices, store data, and run analytics. They integrate easily with ERP or CRM to connect fleet data with business processes.

5. Analytics & AI

This intelligence layer converts raw data into insights. It drives predictive maintenance, route optimization, and anomaly detection, helping managers act before issues escalate.

6. User interfaces

Dashboards, mobile apps, and in-cab tablets visualize the data, giving managers and drivers clear, actionable information.

Key advantages of IoT integration in fleet operations

Understanding the benefits of IoT fleet management solutions in logistics is essential for companies that want to stay competitive, cut costs, and build more resilient supply chains.

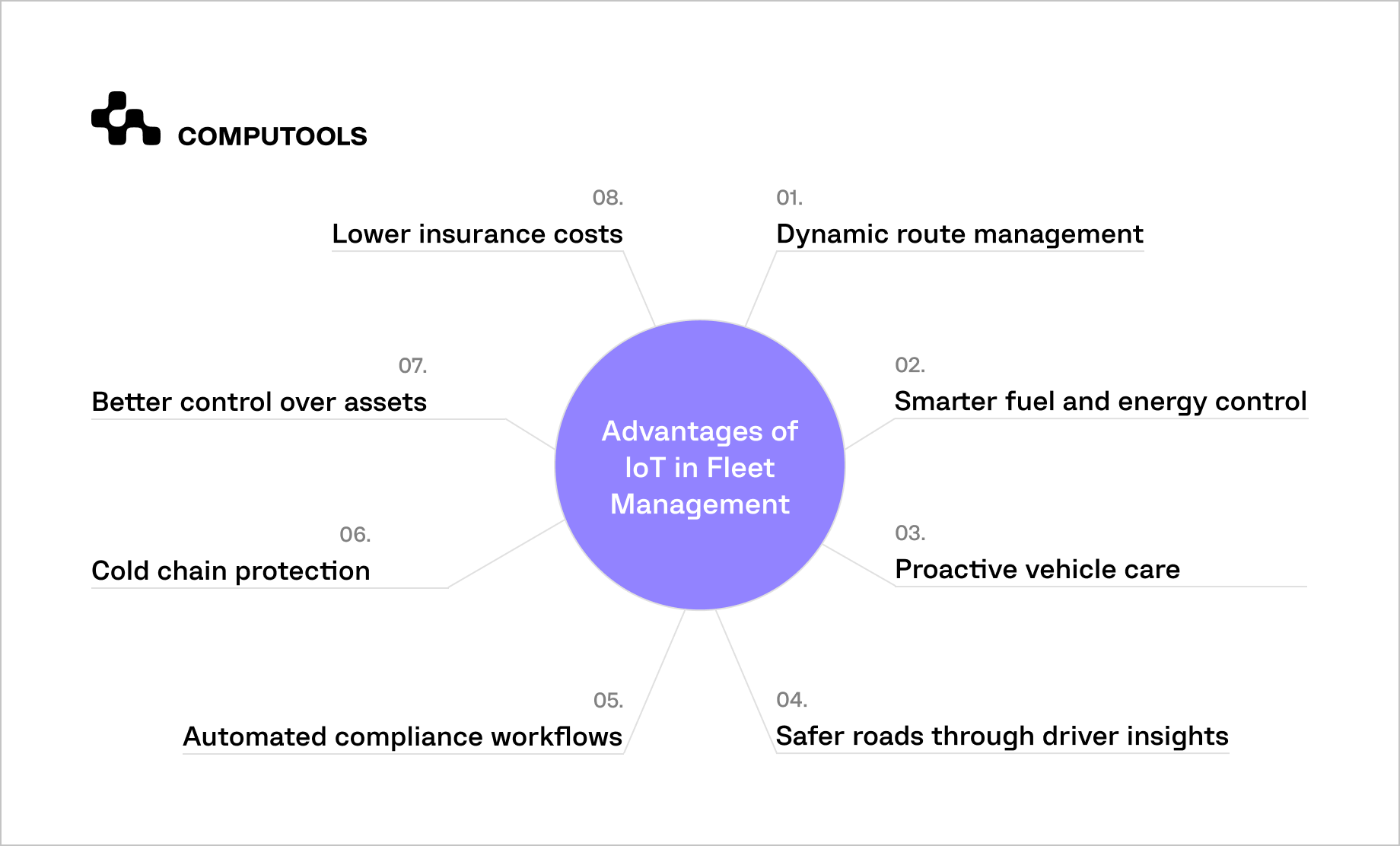

Here are eight key benefits:

1. Dynamic route management. Connected GPS and traffic analytics allow fleets to adjust routes instantly. This minimizes delays, lowers fuel use, and keeps deliveries on schedule, even under unpredictable conditions.

2. Smarter fuel and energy control. IoT systems monitor fuel consumption, idling, and battery health. With this data, managers can pinpoint waste, reduce unnecessary costs, and extend the life of engines and EV batteries.

3. Proactive vehicle care. Continuous monitoring of temperature, vibration, and engine metrics enables predictive maintenance. Fleets fix issues before they escalate, which cuts emergency repairs and maximizes uptime.

4. Safer roads through driver insights. Behavioral telematics tracks speeding, harsh braking, and other risky actions. Addressing these patterns leads to safer drivers, fewer accidents, and lower liability.

5. Automated compliance workflows. Electronic Logging Devices powered by IoT automatically track driving hours and emissions data. This eliminates manual paperwork, reduces human error, and helps fleets meet strict regulatory standards.

6. Cold chain protection. IoT sensors track cargo temperature and humidity throughout the journey for sensitive goods. Real-time alerts prevent spoilage, reducing rejected loads in food and pharma logistics.

7. Better control over assets. IoT doesn’t stop at vehicles. It monitors containers, trailers, and equipment, providing tamper alerts and motion detection. This visibility reduces losses and ensures higher asset utilization.

8. Lower insurance costs. With detailed telematics data, insurers can assess risk more accurately. Fleets demonstrating safe driving records often qualify for discounted premiums and faster claims resolution.

Why it matters

Together, these advantages highlight the broader impact of IoT: end-to-end visibility across the supply chain, quicker and more confident decisions, and tangible financial savings.

By combining real-time tracking, predictive insights, and automated compliance, companies unlock measurable ROI.

The result is clear: logistics operations optimization that delivers lower fuel expenses, minimized downtime, safer fleet operations, and improved customer experience.

We’ve outlined the main benefits, but the picture isn’t complete without looking at fleets’ daily challenges.

Challenges in fleet management today

Fleet managers face recurring industry-wide challenges that impact cost efficiency, safety, and customer satisfaction. Many of these pain points highlight the urgent need for logistics digital transformation:

• High fuel and maintenance costs. Fuel often represents the largest share of operating expenses, while unplanned repairs drive higher costs.

• Unplanned downtime. Vehicle breakdowns or inefficient maintenance schedules lead to service disruptions and lost revenue.

• Limited visibility. Without real-time tracking, managers struggle to monitor vehicle locations, cargo conditions, and driver behavior.

• Regulatory pressure. Compliance with safety, emissions, and labor regulations requires time, accurate reporting, and constant monitoring.

• Driver shortage and safety risks. Recruiting skilled drivers and ensuring they follow safe driving practices remains a persistent issue.

• Cargo security and spoilage. Theft, tampering, and the spoilage of perishable goods continue to threaten margins.

Fleet management use cases

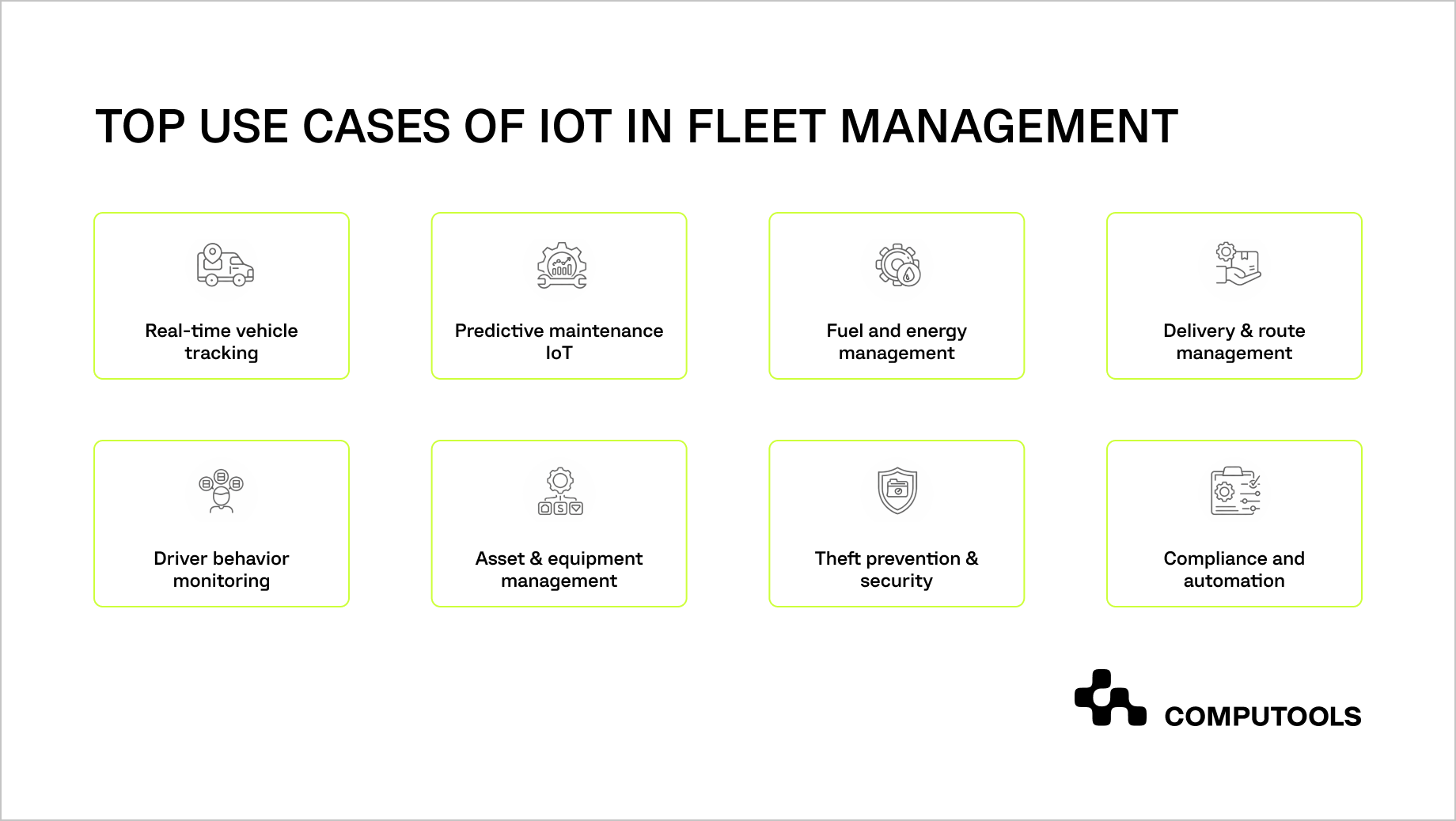

The integration of IoT into fleet management is no longer limited to simple GPS tracking. Today, smart fleet management relies on connected devices and data analytics to deliver real-time insights, reduce costs, and strengthen safety across logistics operations.

Below are the most relevant use cases shaping the industry in 2026.

| Use Case | How It Works | Example | Business Value |

| Real-time vehicle tracking | GPS + telematics provide live vehicle speed, route, and location updates. | UPS | Faster deliveries, theft prevention, optimized routing |

| Predictive maintenance IoT | Sensors monitor engine health, tire pressure, and vibration to prevent failures. | Volvo Trucks | Less downtime, longer vehicle lifespan, cost savings |

| Fuel and energy management | IoT tracks fuel use, idling, and battery health. | Shell | Reduced fuel costs, improved efficiency, and lower emissions |

| Delivery & route management | Dynamic route adjustments based on traffic, weather, and demand. | Amazon | Lower last-mile costs, improved customer experience |

| Driver behavior monitoring | Telematics detect speeding, braking, and idling patterns. | Geotab | Safer driving, fewer accidents, fuel efficiency gains |

| Asset & equipment management | IoT sensors track trailers, containers, and non-powered assets. | DHL | Better asset utilization, reduced idle time, lower capex |

| Theft prevention & security | Geofencing and tamper alerts secure vehicles and cargo. | Industry-wide (Keyfactor report) | Improved security, fewer losses, higher trust levels |

| Compliance & automation | IoT-powered ELDs automate reporting on hours and emissions. | Industry-wide | Easier compliance, reduced paperwork, minimized fines |

Emerging trends influencing IoT in logistics

From greener supply chains to smarter vehicles, IoT is transforming logistics into a connected web of opportunities.

These emerging trends influencing IoT in logistics reveal how IoT improves fleet management and logistics operations, helping companies cut costs, boost safety, and deliver faster than ever.

Here are four key trends setting the pace:

1. AI + IoT for predictive analytics

Artificial intelligence makes IoT data more valuable by identifying hidden patterns and forecasting issues before they disrupt operations. Fleets use this to anticipate maintenance, optimize deliveries, and improve safety.

2. Edge computing in fleet management

Instead of sending all data to the cloud, edge devices process information locally, directly in vehicles or gateways. This reduces latency and allows for instant insights crucial for real-time decision-making.

3. Integration with ERP and CRM systems

IoT platforms increasingly connect to enterprise systems, providing seamless fleet data into finance, HR, and customer management workflows. This helps companies align logistics performance with overall business strategy.

4. Green logistics and CO₂ optimization

Sustainability is no longer optional; it’s a must. IoT sensors and analytics help fleets monitor emissions, optimize fuel use, and support corporate commitments to reduce carbon footprints.

These trends show where the industry is heading: smarter, greener, and more connected. However, to capture these opportunities, businesses need a clear roadmap.

Let’s look at the practical steps of implementing IoT in fleet management, along with the challenges that come with them and the solutions that make adoption successful.

Evaluate how IoT-based fleet tracking can transform visibility, route optimization, and cost control—engage experts to assess architecture and implementation scope.

Implementing IoT: key steps and common challenges

Implementing IoT in fleet management is a multi-step process that requires both strategic planning and technical precision. Done right, it can transform logistics operations, but companies must also prepare for roadblocks.

| Step | Typical challenges | Possible solutions |

| 1. Assess your needs | Companies often rush in and buy gadgets without knowing what problem they’re solving. | Start with an audit: check where costs are leaking (fuel, downtime, safety) and focus there first. |

| 2. Choose the right solution | The IoT market is crowded, and upfront costs for devices and platforms can be intimidating. | Pick scalable tools that fit your size today but can grow with you. Look for vendors experienced in IoT supply chain management and logistics. |

| 3. Integrate with existing systems | Old fleet management or ERP systems may not “talk” easily with modern IoT platforms. | Use gradual integration. Middleware and expert IoT partners can connect sensors and dashboards smoothly. |

| 4. Train your people | Drivers and staff may resist change if they see IoT as “extra work.” | Keep training practical: show how tools simplify compliance, reduce paperwork, and make jobs safer. |

| 5. Scale it up | Expanding to the full fleet creates more data and potential cyber risks. | Use AI analytics for fleet performance monitoring and strong encryption to keep data safe. |

| 6. Ongoing management | Devices need updates, patches, and security checks; they can break or become vulnerable if ignored. | Schedule regular updates and monitoring, or outsource to managed IoT teams to stay current. |

Addressing these steps and challenges early helps companies build a strong foundation to confidently scale their fleets and realize the full benefits of connected logistics.

Future of IoT in fleet: predictions and demand

As transportation IoT technology advances, the industry moves from basic tracking to intelligent automation, prescriptive analytics, and an increasing demand for customized solutions tailored to specific sectors, especially:

1. Market growth and automation

Analysts forecast steady double-digit growth in the IoT fleet market, fueled by deeper automation of routing, asset tracking, and compliance tasks.

Zooming in on fleet management specifically, Verified Market Research projects growth from US$17.49 billion in 2024 to US$119.57 billion by 2031 (CAGR ~30%).

2. From predictive to prescriptive analytics

Today’s predictive tools will develop into prescriptive solutions that automatically identify problems and suggest or carry out the best response.

Reports emphasize shifting from predictive to prescriptive analytics, where IoT platforms detect issues and recommend or automate corrective actions.

3. Rise of autonomous fleets

IoT will be crucial in powering autonomous vehicles and drones, serving as the nervous system connecting sensors, AI, and logistics platforms.

Analysts predict IoT-driven automation will handle most routine fleet tasks by 2030, especially routing, compliance, and maintenance.

4. Demand for industry-specific IoT solutions

From advanced cold chain tracking to real-time parcel visibility, food logistics, pharma supply chains, and e-commerce will drive requests for highly customized IoT setups.

Choosing the right IoT development partner for fleet management

Building effective IoT fleet management solutions takes more than sensors and dashboards; it requires top engineers with IoT expertise and a deep understanding of logistics operations. Without this combination, technology may fail to deliver real business value.

Choosing a partner for fleet management means finding a team that combines software engineering expertise with logistics knowledge, backed by security, certifications, integration skills, and proven results.

Checklist for decision-makers

When evaluating potential partners, make sure they can offer:

• Proven IoT development services with real-world case studies.

• Strong certifications and compliance with ISO, GDPR, and HIPAA.

• Expertise in logistics software development services, from fleet tracking to cold chain monitoring.

• Seamless integration experience with ERP, CRM, and legacy systems.

• Commitment to innovation and long-term support.

Why Computools?

With 250+ engineers and 400+ projects delivered, Computools develops scalable IoT development services and logistics software development services for global clients.

From predictive analytics and real-time monitoring to cold chain management, the company builds unified ecosystems that connect fleets, assets, and enterprise platforms.

Recent success stories from partnering with our company

• LOCARGO (USA) — IoT + AI-powered platform for trucking and delivery boosted revenue 5x in two years.

• Western European Rail Operator — IoT wagon monitoring system cut manual inspections to near zero while enhancing cargo safety and visibility.

Partnering with Computools means turning technology into measurable ROI and future-ready operations.

Contact us today to discuss your fleet’s challenges and explore tailored IoT solutions that match your business goals at info@computools.com

Final insights

IoT in fleet management has become the backbone of modern logistics. Market growth projections show steady multi-billion-dollar expansion, while adoption statistics confirm that companies worldwide are moving from “blind” routing to transparent, data-driven control.

The benefits are clear: real-time tracking, IoT-powered predictive maintenance for fleet operations, fuel optimization, safer driving, and measurable ROI. Emerging trends like AI-powered analytics, edge computing, ERP/CRM integration, green logistics, and connected fleet solutions only strengthen its role in shaping the future of transportation.

IoT for fleet management is not only about tracking; it’s a new model of running logistics operations. Companies that embrace it today are already unlocking efficiency, safety, and resilience, setting a competitive standard for tomorrow’s supply chains.

Computools

Software Solutions

Computools is a digital consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”