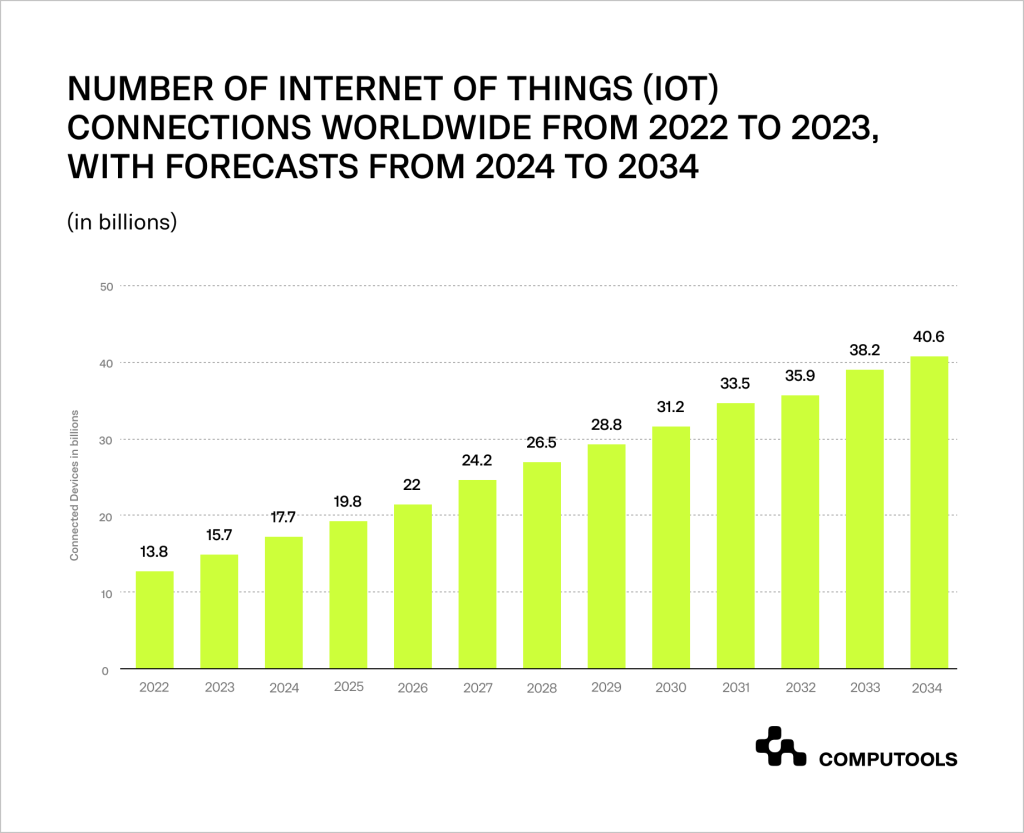

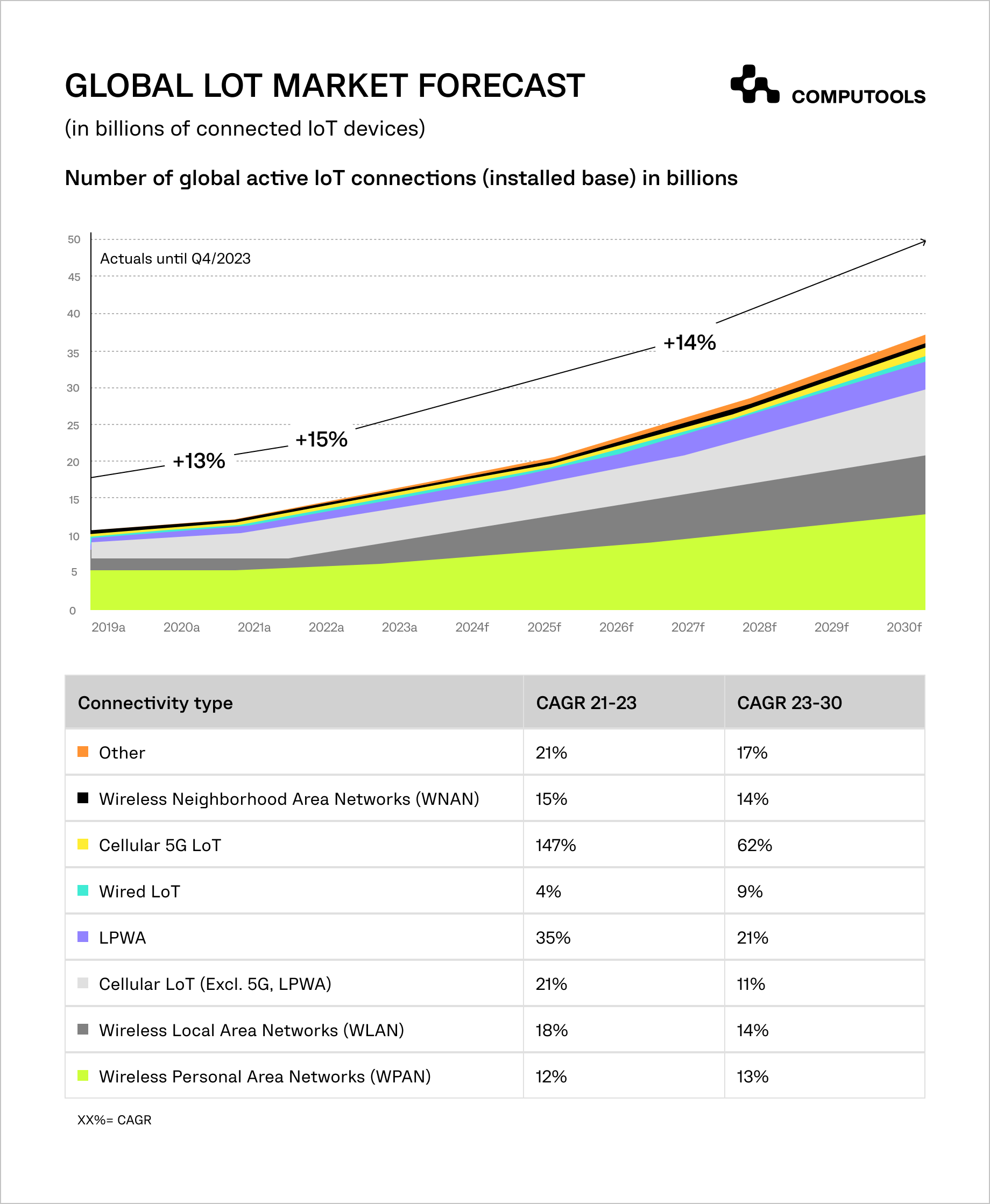

The grocery retail sector generates massive volumes of IoT data from temperature sensors, RFID tags, and POS terminals. Still, without a reliable IoT data pipeline grocery, this information quickly becomes lost instead of valuable. The number of connected IoT devices is projected to increase from 19.8 billion in 2025 to over 40 billion by 2034.

Globally, 1.05 billion tons of food go to waste yearly, with up to 12% lost at retail and 8–10% of global emissions linked to food waste. Meanwhile, 60–80% of IoT projects fail due to poor integration and scalability gaps, proving how fragile IoT ecosystems can be without a strong data infrastructure. For grocery retailers, the absence of resilient, real-time IoT data means delayed insights, inventory waste, lost profit, and rising emissions issues that modern data architecture can directly prevent.

At Computools, we assist grocery and food-tech companies in understanding their data instead of being overwhelmed by it. With our retail software development services, we build systems that connect IoT sensors, analytics, and cloud platforms into one living network. The goal isn’t just to collect numbers but to turn them into actions, predicting demand, preventing waste, and keeping shelves stocked with fresh products. Our IoT software solutions allow retailers to see what’s happening across every warehouse, truck, and store in real time.

How Computools designed IoT data pipelines to make grocery retail more efficient

One of our clients, E-Feller, a Finnish startup, aimed to reduce food waste throughout global grocery and supply chains by developing a smarter way to manage data. The company needed a system to collect, clean, and process information from thousands of IoT sensors, temperature trackers, RFID tags, and GPS devices monitoring real-time product conditions, shelf life, and logistics. Their goal was simple: use accurate data to make faster decisions and prevent losses before they happen.

As part of our IoT development services, Computools’ engineers designed and implemented a scalable data pipeline design for IoT solutions that connects devices, databases, and analytics tools into one continuous flow. The platform gathers, filters, and visualizes sensor data in real time, ensuring that every temperature change or delayed shipment triggers an immediate response.

The results speak for themselves: E-Feller reduced food waste by 75%, optimized inventory turnover, and improved delivery efficiency. What began as an MVP evolved into a scalable data ecosystem capable of supporting large grocery retail IoT solutions across regions.

The E-Feller project laid the groundwork for sharing our practical approach to designing data pipelines for IoT in grocery retail that turn complex sensor data into real-time insights and measurable results.

How to design data pipelines for IoT in grocery retail

Designing a data pipeline for the grocery retail sector goes beyond connecting devices; it transforms billions of signals into one intelligent ecosystem. Based on our experience with projects like E-Feller, we’ve defined a step-by-step framework that helps retailers build IoT-enabled smart retail solutions for operational efficiency, real-time decision-making, and sustainability.

Step 1. Define objectives and data flows

Every effective IoT architecture for grocery supply chain starts with a clear definition of success. Retailers must begin by pinpointing their desired outcomes: reducing food waste, maintaining freshness, improving demand forecasting, or optimizing delivery routes. These objectives determine how data should be collected, connected, and interpreted.

The foundation lies in understanding data in grocery retail industry where it comes from and how it moves. Temperature sensors, RFID tags, GPS trackers, POS terminals, and warehouse software systems continuously generate massive amounts of information. Each data stream must be mapped to a tangible business function: a temperature reading tied to product quality, a location signal linked to delivery timing, or a sales transaction connected to replenishment cycles.

For example, the E-Feller case, where the Computools team began by auditing every data source across the supply chain to identify where information had the most operational value. By tracing how temperature, logistics, and stock data influenced shelf-life control, the team built a roadmap where every data byte served a measurable purpose.

This early precision prevented data overload, ensured interoperability, and laid the groundwork for analytics that directly supported business outcomes.

Step 2. Build a cloud-based foundation

Scalability and resilience begin in the cloud. Modern grocery supply chains produce terabytes of operational data daily, including temperature logs, delivery timestamps, in-store foot traffic, and checkout transactions. Managing this complexity requires IT infrastructure that scales with data growth and remains reliable during peak demand.

A cloud-based IoT data pipeline design enables seamless connectivity, elastic scaling, and secure multi-location data synchronization. Cloud services automatically balance the load when thousands of IoT nodes send data simultaneously, ensuring continuous operation during major retail events or logistics surges. They also provide unified storage for real-time and historical data, giving retailers instant access to insights while maintaining long-term analytical depth.

Computools implemented a hybrid setup in the E-Feller MVP that combined edge gateways with centralized cloud storage. This architecture ensured stable, low-latency data transmission even when local networks experienced interruptions. The system maintained real-time freshness monitoring and delivery tracking by syncing sensor data between on-site devices and cloud servers, a model now scalable across multiple grocery distribution centers.

Step 3. Collect and unify sensor data

IoT systems only reach their full potential when data speaks the same language. Grocery retailers often face fragmented systems, POS data in one format, sensor data in another, and logistics data in another. Without integration, insights remain locked in silos.

Data integration for IoT in retail solves this by merging diversified sources into one consistent framework. APIs, middleware, and data connectors translate data from different devices and applications into standardized, analytics-ready formats. This creates a foundation for operational visibility, enabling retailers to view real-time sales, storage, and logistics data through a single lens.

At the same time, an IoT sensor data pipeline in retail ensures that these streams remain continuous and reliable. It validates, filters, and processes readings from temperature, humidity, or location sensors before they enter analytical systems. This guarantees accuracy and allows predictive models to react instantly, from detecting early spoilage risks to optimizing replenishment cycles.

Working on the E-Feller project, Computools built a hybrid integration layer connecting IoT gateways, RFID tags, and cloud analytics tools into one real-time ecosystem. Each stream, whether from sensors or logistics software, was normalized and synchronized, eliminating data gaps and improving transparency across the grocery supply chain.

Step 4. Process and enrich data in real time

Once the data is collected and unified, it must be transformed into intelligence. Through stream processing frameworks like Kafka, Spark, or AWS Kinesis, data flows continuously rather than in batches, allowing retailers to respond instantly to temperature, demand, or delivery timing changes.

This is the core of data engineering for IoT retail systems, converting unstructured sensor readings and POS logs into high-quality, actionable data. Cleaning, validation, and enrichment occur automatically: duplicates are removed, missing values are corrected, and contextual metadata (like location or supplier) is attached.

In the E-Feller project, Computools implemented a streaming layer that performed continuous quality checks and anomaly detection. When temperature deviations or delays occurred, the system triggered alerts and automatically synchronized with logistics dashboards. This reduced reaction time from hours to minutes and helped maintain product freshness throughout the supply chain.

Real-time enrichment also enabled predictive analytics. By analyzing data trends, the platform could forecast spoilage risks or inventory imbalances before they occurred, turning the pipeline into a monitoring and decision-support tool.

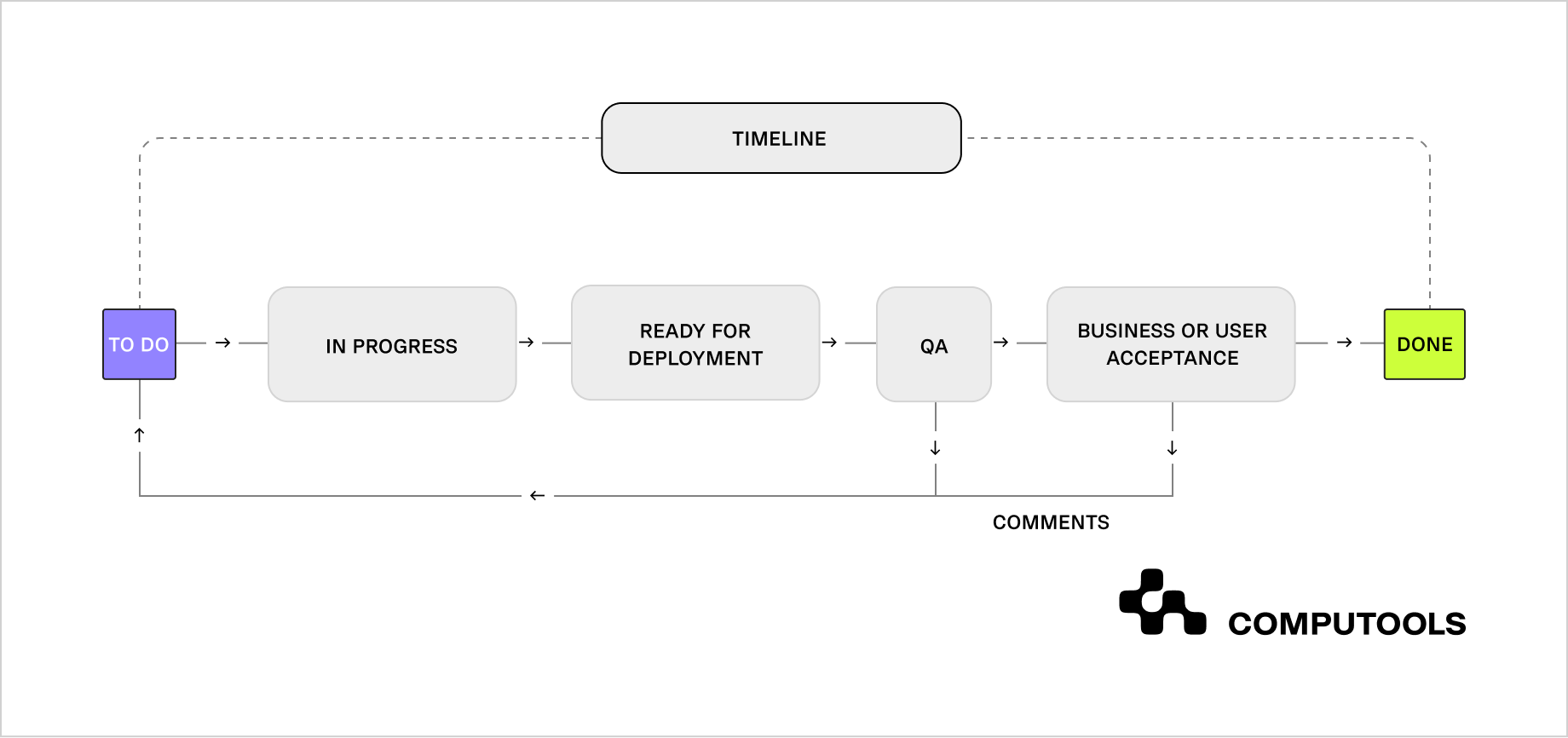

The diagram illustrates the structured workflow used by Computools to design and implement the data pipeline from IoT sensor integration and data validation to cloud synchronization and analytics.

Step 5. Store, analyze, and forecast

Processing is only the beginning; insights are born when data is preserved, structured, and analyzed. A strong storage strategy blends data lakes for raw telemetry with data warehouses for structured analytics, providing a foundation for historical analysis and AI-driven forecasting.

This phase powers analytics, where temperature trends, sales data, and delivery logs merge to create a full operational picture. Retailers can identify inefficiencies, refine replenishment schedules, and improve product mix across locations.

At Computools, the E-Feller platform used a layered storage architecture, one tier for real-time operational data and another for analytical and historical insights. This setup allowed the client to track patterns over time, from recurring cold-chain issues to regional demand variations.

These insights fuel grocery inventory optimization with IoT, ensuring that perishable goods are stocked based on actual consumption rates, not assumptions. By continuously learning from stored data, the platform supported smarter forecasting, reduced overstock, and minimized food waste.

The result was a leaner, more sustainable retail model, fewer expired products, lower energy costs, and better alignment between supply and demand.

Step 6. Visualize insights and automate responses

Visualization brings clarity, translating technical metrics into intuitive, actionable insights. In real time, managers can monitor temperature compliance, logistics performance, and shelf-life status through dashboards, alerts, and digital twins. Interactive visualization tools connect operational teams directly to live data streams, allowing instant response to anomalies or inefficiencies.

This visibility layer turns IoT-enabled solutions into intelligent control systems rather than static dashboards. In the E-Feller project, Computools designed a role-based dashboard where managers could track inventory freshness, logistics status, and CO₂ reduction metrics at a glance. Automated alerts notified teams when storage temperatures drifted beyond safe limits, preventing spoilage before it occurred.

Automation extended beyond monitoring: specific actions, like rerouting delayed shipments or adjusting storage parameters, were executed directly through the interface. This closed the loop between data insight and business action, eliminating delays, improving decision accuracy, and reducing human error.

Step 7. Design for scalability and resilience

A modern, scalable IoT data pipeline solutions must be ready for constant evolution. Grocery networks expand, sensors multiply, and regulatory standards shift. Building with open APIs, modular microservices, and automated monitoring ensures pipelines adapt without downtime. The ability to handle billions of transactions while maintaining compliance and uptime defines digital maturity in grocery retail.

From defining data flows to automating insights, every layer of an IoT pipeline plays a strategic role in retail transformation. Projects like E-Feller prove that retailers can achieve measurable sustainability goals and continuous operational optimization when technology, analytics, and cloud infrastructure work together.

This structured approach to IoT data pipelines in grocery retail turns fragmented data streams into a single intelligent system that powers smarter decisions, faster reactions, and stronger results across the grocery retail ecosystem.

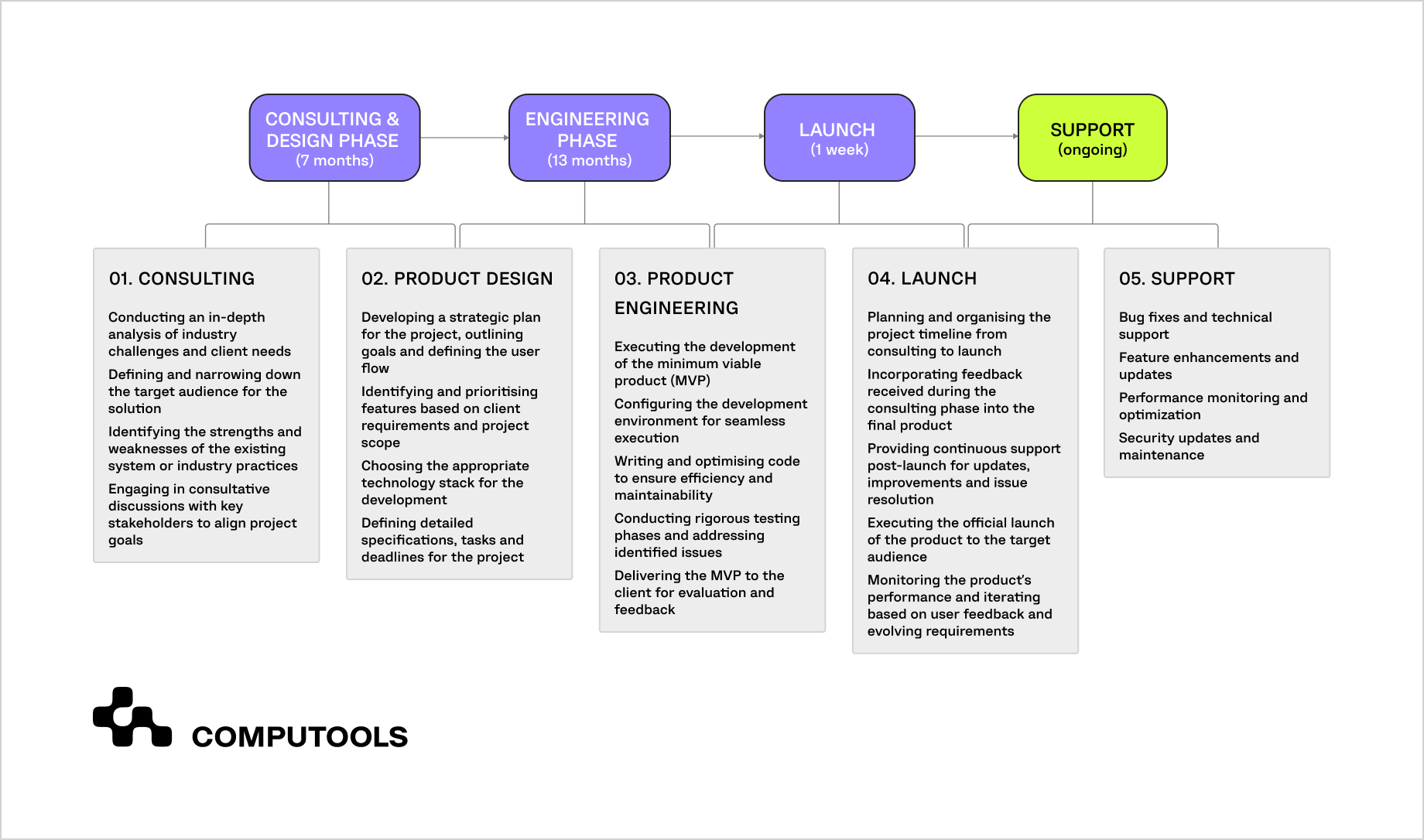

The timeline illustrates the E-Feller MVP phases, from data flow mapping to cloud deployment and analytics, showing how each IoT pipeline step boosted scalability and reduced waste.

For a deeper understanding of how IoT prototypes speed up digital transformation in grocery and retail, check out our guide on developing IoT MVPs for supply chains: How to Build IoT MVP for Grocery and Retail Supply Chains.

Tomorrow’s grocery leaders will be data-driven today. Discover how IoT data pipelines can connect every shelf, sensor, and shopper insight.

Challenges and benefits of implementing an IoT data pipeline grocery retail

Implementing an IoT data pipeline grocery retail unlocks huge opportunities for efficiency, sustainability, and customer insight; it also brings operational and technical challenges. Building resilient, scalable systems demands balancing investment, security, and integration complexity with measurable returns.

The table below outlines retailers’ main obstacles and the tangible benefits an effective pipeline strategy can deliver.

| Challenges | Benefits |

| High implementation and maintenance costs for IoT infrastructure and sensors. | Optimized resource use and long-term ROI through automation and data-driven operations. |

| Complex integration of multi-source data and legacy software systems. | Centralized control and faster insights enabled by effective IoT data management. |

| Security and privacy vulnerabilities due to multiple connected devices. | Strengthened compliance, customer trust, and secure data flow across the ecosystem. |

| Limited in-house technical expertise in IoT and analytics. | Skill development and innovation through collaboration with technology partners. |

| Dependence on stable connectivity and scalable architecture. | Continuous visibility and responsiveness are supported by real-time data processing in retail. |

| Regulatory pressure on food safety, traceability, and sustainability. | Automated compliance and sustainability tracking powered by retail analytics with IoT data pipelines. |

If your next goal after IoT adoption is to build a scalable retail marketplace, check out our overview of top marketplace app developers for retailers: Best Marketplace App Development Companies for Retailers.

Future trends and innovations in IoT for grocery retail

The grocery retail IoT integration and data pipelines ecosystem is evolving rapidly, redefining how stores source, sell, and operate. In 2024, the global IoT retail market was valued at $66.44 billion and is projected to reach $488.53 billion by 2033, growing at a CAGR of approximately 24.5%.

At the same time, the number of connected IoT devices worldwide is expected to surge from 18.8 billion to 40 billion by 2030, a shift that will exponentially increase the volume of data retailers must process and analyze in real time. Below are some trends that forecast our future in IoT for grocery retail.

1. AI-driven personalization and predictive insights

AI software solutions combined with IoT will enable ultra-personalized shopping. Smart assistants will analyze shopper behavior and IoT sensor data to recommend products, optimize pricing, and forecast demand, creating a seamless, adaptive shopping journey.

2. Autonomous and frictionless stores

Following the model of Amazon Go, more grocery chains will introduce fully autonomous stores powered by IoT sensors, cameras, and computer vision. Customers will walk out without waiting in line, as the system automatically registers products and payments.

3. Smarter supply chains with blockchain and analytics

IoT and blockchain solutions will merge to create transparent, traceable supply chains. From farm to shelf, every step will be verifiable. Predictive analytics will use sensor data to prevent disruptions, optimize routes, and reduce waste.

4. Sustainable sourcing and smart agriculture

IoT will extend beyond retail floors into fields. Sensors and drones will monitor soil, crops, climate conditions, and control animal health allowing farmers to use fewer resources while improving yield and quality. Retailers will track environmental impact to ensure ethical sourcing.

5. Enhanced in-store experience and ar integration

Augmented reality will reshape how people shop. Customers will visualize products, ingredients, or offers through AR apps. Smart carts will display live recommendations, helping shoppers find what they need faster.

6. Energy efficiency and waste reduction

Based on store occupancy, smart energy systems will manage lighting, cooling, and heating. IoT-based expiry and waste monitoring will help reduce spoilage and support donation programs.

7. Data security and infrastructure resilience

As the number of devices grows, cybersecurity becomes mission-critical. Encrypted communications, blockchain-based verification, and zero-trust architectures will form the backbone of reliable IoT infrastructure.

In the near future, IoT data pipeline grocery systems will evolve from data transport mechanisms into intelligent, predictive engines capable of interpreting sensor data instantly and driving autonomous retail operations.

Successfully navigating these emerging trends requires deep expertise in IoT architecture, data engineering, and retail operations, which are the exact strengths our team offers in every project.

Why choose Computools

We combine technology expertise with hands-on results. In the E-Feller project, our team helped cut food waste by 75% using smart IoT tracking and real-time analytics, a clear example of how data can reshape grocery operations.

With experience in grocery retail software development, we build systems that connect stores, sensors, and supply chains into one data flow. Our real-time IoT data processing for grocery stores keeps insights live and actionable. In contrast, IoT-enabled analytics in grocery industry helps predict demand, reduce losses, and make every decision smarter.

Got a challenge to solve? Email us at info@computools.com, and we’ll help you turn your data into results.

Computools

Software Solutions

Computools is an IT consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”