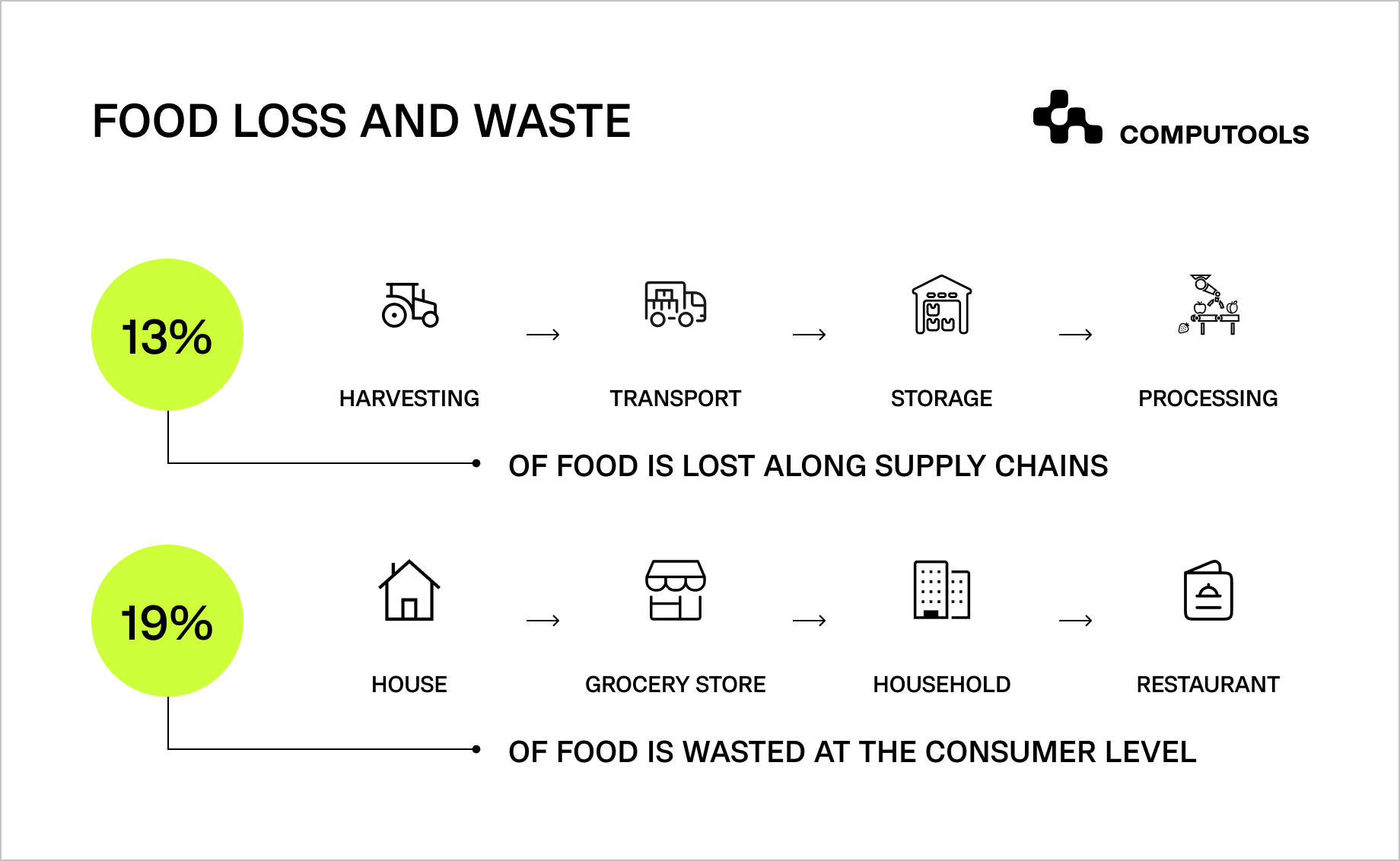

Food waste has become one of the most pressing challenges for the retail industry. About 13% of food is lost between production and retail, while another 19% is wasted at retail and consumption levels. Beyond the financial losses, food waste is responsible for 8–10% of global greenhouse gas emissions, making it both an economic and environmental crisis.

For retailers, the challenge is reducing spoilage and gaining the visibility and control needed to optimize inventory, protect margins, and meet customer expectations. This is where an IoT food waste solution makes a difference.

Computools facilitates this transformation by providing retail software development services and IoT development services. With over 400 projects delivered worldwide, including more than 20 in the retail sector, we have helped enterprises and mid-sized retailers modernize legacy systems, connect devices and sensors into unified platforms, and implement real-time analytics to reduce losses and improve efficiency.

How we solved the challenge of cutting food waste with a custom IoT monitoring system

In collaboration with E-Feller, a Finnish startup, we developed a platform that integrates IoT sensors, RFID tags, and real-time analytics to track product expiration dates and monitor the flow of goods across every stage of the supply chain. The system enabled efficient inventory management, optimized logistics, and improved demand forecasting.

The result was a 75% reduction in food waste and a significant increase in supply chain efficiency. This case proved that a custom food waste monitoring system can minimize losses and become a strong competitive advantage in the market.

In the next section, we will explore step by step how such grocery retail software solutions help reduce food waste with IoT and what tangible benefits they deliver for retailers and suppliers.

How to reduce food waste with a custom IoT monitoring system?

Every year, the world loses more than 1.3 billion tons of food. This is a massive financial loss for businesses and a severe environmental burden, as food waste accounts for around 8% of global greenhouse gas emissions.

In monetary terms, this adds up to more than $940 billion in business losses yearly, causing major environmental damage through CO₂ emissions, wasted water, and misused land resources. The biggest inefficiencies occur in retail and logistics, where gaps in storage control, demand forecasting, and inventory visibility remain weak.

Integrating IoT sensors, RFID tags, and analytics into one platform enables businesses to improve supply chain visibility, reduce waste, and boost operational efficiency. Here’s how it works in practice.

1. Controlling storage and transportation conditions

One of the most significant contributors to food loss occurs before products reach the store, during their time in fields, trucks, and warehouses. A minor disruption in the cold chain can significantly cut shelf life by several days, resulting in substantial waste throughout the supply chain.

By leveraging IoT sensors for food safety, we can seamlessly monitor critical factors such as temperature, humidity, and geolocation in real time. This level of transparency in cold chain management ensures that any deviations trigger instant alerts, allowing quick actions.

In our project with E-Feller, we strategically integrated sensors at multiple checkpoints, empowering managers with unparalleled visibility into transport and storage conditions. This proactive approach helps prevent spoilage and guarantees that high-quality products reach warehouses and retail outlets without compromise.

2. Monitoring expiration dates

Expired stock is a silent profit killer. Manual inventory checks often miss items nearing expiration, which leads to unnecessary waste that could be avoided.

Custom IoT monitoring solutions automate this process with RFID tags and barcode scanning, enabling businesses to apply FIFO (First In, First Out) and FEFO (First Expired, First Out) without human error.

In the E-Feller platform, algorithms automatically flagged items close to expiration. This gave managers time to adjust promotions or logistics and ensure products were sold instead of discarded.

3. Accurate demand forecasting

Overproduction is one of the most significant and costly contributors to food waste. Many businesses struggle with precise forecasting, often resulting in overordering and excess stock that inevitably spoils.

However, IoT systems have the potential to revolutionize demand prediction. By harnessing data on stock turnover, storage conditions, and real-time sales, these systems empower businesses to reduce unnecessary purchases and streamline their production processes dramatically.

Take E-Feller, for instance. We forecasted customer demand weeks in advance by integrating IoT sensor data with advanced predictive analytics. This proactive strategy allowed them to perfectly align their purchasing and inventory management with genuine consumer needs, leading to a remarkable decrease in surplus stock and a more sustainable approach to food management.

4. Enabling transparency and rapid response

Problems in the supply chain escalate quickly if managers only discover them after the fact. Businesses need real-time visibility and the ability to act before waste occurs.

IoT-powered dashboards provide managers with a complete overview of product conditions and stock levels across all supply chain stages. Automated alerts flag issues like temperature spikes, shipment delays, or products nearing expiration, allowing teams to take immediate corrective action. With E-Feller, alerts allowed managers to respond to problems within minutes, preventing costly product losses and ensuring higher operational reliability.

5. Integration across the entire supply chain

Food waste is a multifaceted challenge that impacts every stage of the supply chain, from production and logistics to retail and consumer engagement. Relying on tools that address only one segment can lead to critical blind spots and hinder effective solutions.

With end-to-end IoT monitoring services, a food waste tracking system connects seamlessly with ERP and WMS platforms, ensuring data flows across the entire value chain. Such seamless connectivity ensures that data flows consistently across the value chain, creating a powerful digital ecosystem. This environment empowers decision-makers with complete information, enabling them to act confidently rather than relying on fragmented data.

For E-Feller, Computools provided robust API integrations that linked the IoT platform with other enterprise systems. This strategic integration streamlined data sharing and synchronization from production to retail, eliminating bottlenecks and significantly enhancing stakeholder coordination. Embracing this solution drives efficiency and transforms food waste management into a more compelling initiative.

The result of this holistic approach was striking: a 75% reduction in food waste and a significant boost in supply chain efficiency. This demonstrates that smart IoT technology for reducing food spoilage in grocery retail is more than just a trend, but a proven solution to cut costs, enhance sustainability, and provide businesses with a measurable competitive advantage.

Sometimes the smartest way to start with IoT is small. Building an MVP helps test assumptions and scale only what works. Explore this idea in Considering MVP: Why and When It Is Crucial For Business.

Nearly 30% of all food is lost or wasted before it ever reaches consumers. With a custom IoT monitoring system, your business can track, predict, and prevent waste at every stage of the supply chain.

How to solve food waste with IoT: challenges and solutions

| Challenge | IoT Solution | Business Benefits | Example (E-Feller) |

| Overproduction due to inaccurate forecasting | Predictive analytics powered by connected device monitoring software and real-time sales data | Reduced leftovers, more accurate ordering, and lower production costs | Analytics in the platform helped E-Feller forecast demand and cut surplus |

| Lack of transparent waste tracking | IoT sensors and RFID tags for real-time monitoring | Visibility across all supply chain stages, better control, faster response | E-Feller’s IoT food waste solution tracked product expiration dates at every checkpoint |

| Weak inventory management | Automated stock rotation (FIFO/FEFO), manager dashboards | Lower spoilage, optimized warehouse management operations, and less manual work | The platform notified which products should be used first |

| Spoilage from poor storage or logistics | IoT temperature & humidity sensors, GPS tracking | Cold chain control, improved food safety, and longer shelf life | E-Feller integrated sensors to avoid losses during transportation |

| Limited real-time data | Centralized dashboards with instant alerts | Faster decision-making, reduced risks, operational agility | Real-time sensor data enabled E-Feller to react immediately |

| High disposal and logistics costs | IoT in food supply chain management for optimized purchasing and delivery | Lower waste disposal costs, higher ROI, reduced CO₂ emissions | Result: 75% food waste reduction, streamlined supply chain |

Future trends in IoT food waste solutions

1. AI-powered predictive analytics

AI development is extending the value of the IoT food waste solution. AI enables precise demand forecasting by analyzing historical sales, seasonal demand, weather, and consumer trends, cutting overordering and spoilage.

Research by Gustavsson shows that this kind of Food waste reduction technology minimizes losses at scale. AI also helps monitor shelf life and send proactive alerts, keeping perishable goods in safe circulation.

2. Blockchain for traceability and accountability

Blockchain, combined with IoT technology for food industry, creates secure, tamper-proof supply chain records. This improves traceability from farms to retail shelves and ensures accountability.

Studies confirm that IoT-based monitoring applications paired with blockchain help detect inefficiencies such as improper storage or delivery delays and build consumer trust through transparency.

3. Robotics and automation

Robotics will increasingly support waste management by automating sorting, packing, and redistribution. When paired with remote monitoring with IoT technology, these systems reduce human error, accelerate workflows, and ensure consistent quality control across multiple sites.

4. Integrated smart ecosystems

The future is about convergence: AI, blockchain solutions, robotics, and IoT working together in one intelligent ecosystem. Imagine smart kitchens where IoT sensors track freshness, AI engines optimize purchasing, robots automate processes, and blockchain ensures sustainability data is verifiable. This end-to-end integration boosts efficiency while cutting food waste dramatically.

5. Smart cities and consumer engagement

As urban areas aim for zero-waste targets, IoT-powered systems will drive innovations like dynamic waste collection, real-time redistribution, and intelligent recycling systems.

On the consumer side, connected devices may offer personalized insights and incentives, making food waste reduction a shared responsibility between businesses and individuals.

Checklist: how to choose the right partner for a custom IoT monitoring system

1. Proven expertise in IoT and retail software. Check whether the vendor has a strong retail and supply chain solutions portfolio, not just theoretical knowledge.

2. Capability to deliver IoT-powered food waste prevention solutions for retailers. The right softare partner should be able to integrate sensors, RFID, and analytics into one platform that reduces waste and optimizes processes.

3. Smart inventory management with IoT. Look for IoT-driven tools that provide real-time visibility into inventory, automate FIFO/FEFO principles, and prevent overproduction.

4. Expertise in IoT supply chain monitoring for food industry and IoT-enabled food storage management. The right partner should demonstrate hands-on experience monitoring supply chains, controlling cold chain conditions, and managing food storage with IoT technologies. This ensures accurate demand forecasting, reduced spoilage, and overall operational efficiency.

5. Security, scalability, and compliance. ISO certifications, adherence to international standards, and experience with enterprise clients ensure the system will be secure, scalable, and future-ready.

Looking for more insights into top tech partners for retail? Don’t miss Top 15 Custom Retail Software Development Companies in 2025.

Why Computools is the right partner

Computools has proven expertise in IoT development services that deliver measurable impact. A key example is the collaboration with Finnish startup E-Feller: by integrating IoT sensors, RFID tags, and real-time analytics, we helped the client achieve a 75% reduction in food waste and significantly improve supply chain efficiency.

Beyond this project, our team specializes in retail software development, designing solutions that connect every stage of the value chain from production to distribution to in-store operations. With hands-on experience in IoT applications in food waste prevention, we provide more than just technology: we deliver complete, scalable ecosystems that integrate with ERP/WMS systems and adapt to international markets.

This combination of technical depth and practical results makes Computools the ideal partner for businesses looking to transform food waste management into a competitive advantage.

Ready to explore how Computools can help you reduce food waste and optimize your supply chain? Contact us at info@computools.com to discuss your project.

Computools

Software Solutions

Computools is an IT consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”