Despite the growth of the global WMS market, some researches show that around 80% of warehouses still lack automation in their operations.

High initial investments and uncertainty about what technology to implement are the main factors hindering the adoption of new technologies.

However, the forecasted advancement in cloud technologies and the need for digitalization fuel the adoption of warehouse management systems (WMS) among small and medium-sized businesses.

WMS systems allow manufacturing, retail, and logistic companies to facilitate and automate the processes of picking, packing, and shipping products.

This article discusses the main advantages of a warehouse management system and the necessary functionality for efficient warehouse management.

What is a Warehouse Management System (WMS)?

A warehouse management system consists of two major components:

• Custom or cloud-based software and IT infrastructure.

• Hardware components.

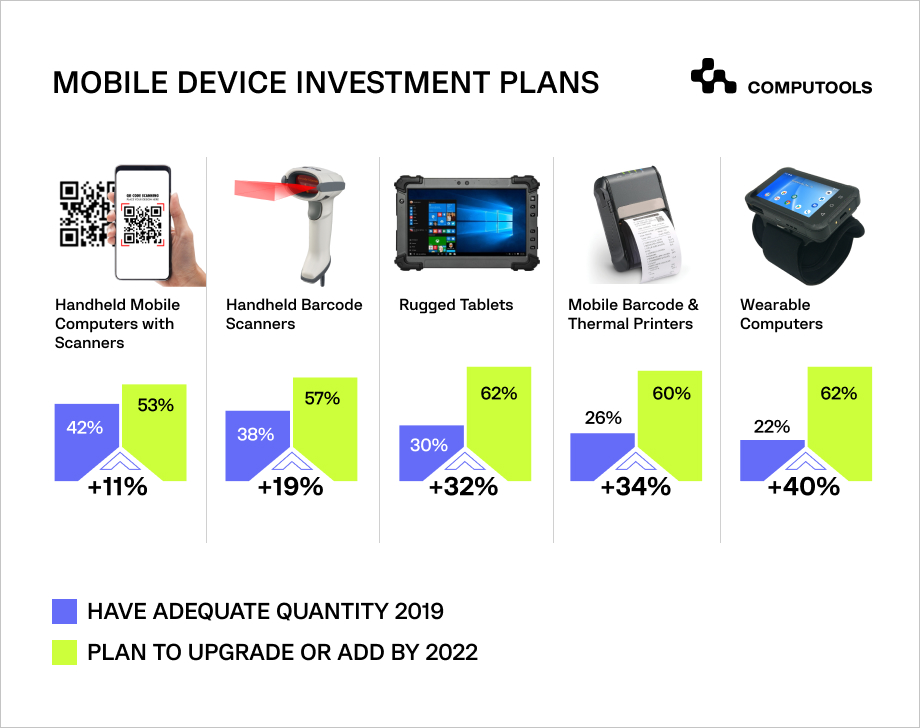

When it comes to hardware, WMS infrastructure consists of the following components:

• RFID chips to track employees’ locations

• Barcode scanners

• Client devices (PCs, tablets, smartphones)

• Barcode printers

• Data collection terminals

• Radio transmitters

• Servers

Depending on the size of the warehouse and business needs, the functionality and number of components of the warehouse management system can vary.

One of the essential criteria of the WMS system is the ability to integrate it with other software and business applications, which allows businesses to link and optimize all enterprise business processes.

Depending on the size of the warehouse and business needs, the functionality and number of components of the warehouse management system can vary.

One of the essential criteria of the WMS system is the ability to integrate it with other software and business applications, which allows businesses to link and optimize all enterprise business processes.

Learn more about supply chain automation and warehouse systems from our experts!

Contact us →Understanding WMS benefits

Implementing a warehouse management system provides a business with many benefits ranging from quick decision-making based on real-time data to reduced costs for order processing and shipping.

Let’s take a look at some of the main WMS benefits.

1. Transparent data for quick decision-making

A warehouse management system shows all the essential information about inventory, allows employees and executives to assess the warehouse’s current situation, and quickly identify high-risk factors such as theft, damaged goods, their locations, etc.

Increasing staff productivity is also helpful. Using RFID and barcode technology, employees can organize products efficiently, and monitor and maintain equipment and inefficiencies within the warehouse.

2. Increase the speed of order fulfillment

The market is getting drastically more competitive as consumers expect their goods as soon as possible, requiring organizations to reduce order fulfillment from days to hours. A warehouse management system improves processes and takes order delivery to the next level.

Backed up by mobile terminals or other devices that automate manual operations, your staff can pick and pack orders faster, significantly reducing processing and delivery times.

3. Reducing warehouse processing costs

50% of warehouse operating costs go to picking operations.

Therefore, optimization and automation of such operations as slotting, packing, or receiving orders, will inevitably lead to cost reduction for goods processing.

Warehouse management software helps organize the right product in the right place at the right time.

Clear distribution of goods in the warehouse and, most importantly, transparency about products’ locations and shelf life is paramount for cost reduction. To make correct and timely management decisions, warehouse managers must always be aware of delivery schedules, the volume of inventory, and order fulfillment statuses.

4. Minimizing errors

Handheld computers, barcode scanners, and wearable computers significantly reduce the time to process merchandise and the risk of errors.

Employees can scan the barcode of goods during all warehouse processes: picking, packing, shipping, receiving, etc. The warehouse management system controls crucial employees’ operations, warns them about critical mistakes, automatically keeps track of the goods, and transmits the data to the accounting system in real time.

5. Time savings

A warehouse management system reduces the time to perform order picking and delivery.

This is mainly done through data collection terminals that read barcodes from products and transmit data to the warehouse system, ensuring real-time stock location visibility and reduction in manual tasks.

Warehouse management system functionality

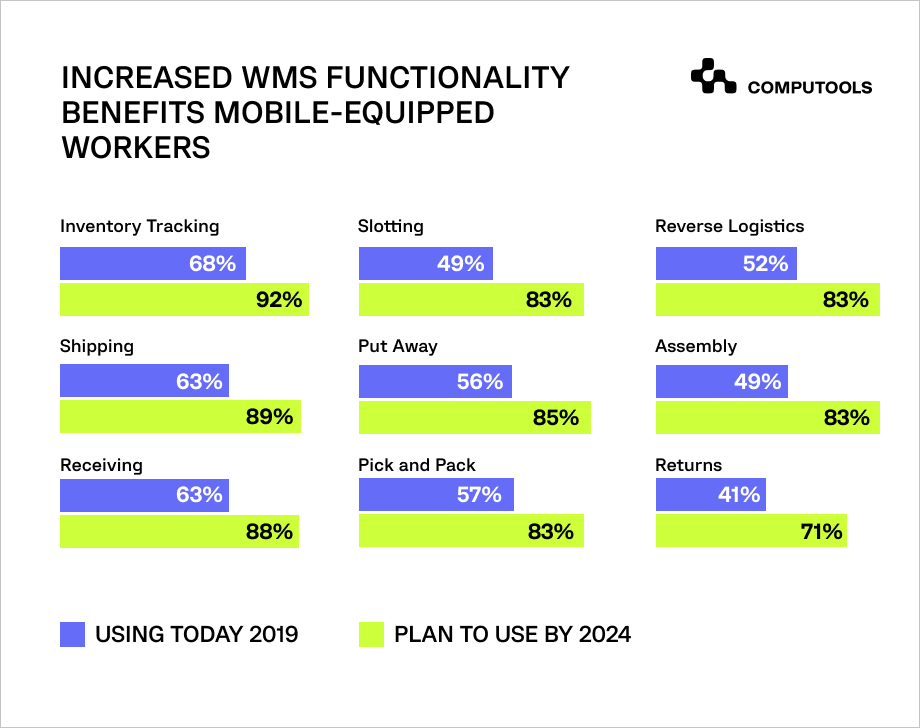

The features of warehouse management system are tailored to the business needs, the size of the enterprise, and its current IT infrastructure. However, the core WMS features revolve around operations related to stocking, receiving, storing, picking, packaging, and dispatching goods.

1. Receiving goods

The module of receiving goods works according to the preconfigured business processes, compliance with which is a prerequisite for all operations. It can be customized according to the requirements of the system users, but its primary goal is to ensure the receipt of goods with minimal errors.

2. Placing goods

The storage module keeps records of goods and provides employees and executives with up-to-date information about their quantity, minimizing the overstocking of the warehouse with unnecessary items. Saving warehouse space is achieved through optimal distribution and storage of inventory.

3. Storage automation

The storage feature allows executives and managers to simulate effective storage schemes for various goods, considering their characteristics, such as the weight, demand, or inventory turnover rate.

Here, various scenarios for optimal warehouse layout can be applied, from minimization of the carbon footprint and energy consumption to the strategic layout for agricultural and food products.

Multiple layout factors can be considered to ensure that warehouse logistics work efficiently.

4. Employee management

The employee management module helps maintain a large number of staff.

This can be achieved through the following functionality:

• Step-by-step instructions for each task;

• Control over the execution of tasks by tracking RFID tags on packaging and employees;

• Calculation of staff productivity;

• Scheduling tasks for cargo handling;

• Assigning tasks to the least busy staff member;

• Dividing staff members into groups for specific tasks.

5. Document management

Document management features can automate all resource-intensive paperwork operations.

This module can ease the pain of generating thousands of reports about each product that enters the warehouse.

Additionally, warehouse staff can access the common database and quickly find all the necessary information for fast, high-quality work.

6. Preparing and packaging goods

A warehouse management system provides quality order packaging and dispatching, which means the process will be done according to the warehouse’s standards, FIFO, FEFO, FPFO, and LIFO. This guarantees that goods will be packed more quickly and delivered to the right addresses at the right times.

In conclusion: choosing a warehouse management system

Logistics and warehouse operations have always been considered inherently complex to digitalize.

However, today’s WMS market offers many systems that small and medium-sized businesses can quickly adopt. These can be simple boxed solutions or complex warehouse management systems.

To choose a WMS system that’s in line with the foremost goals of warehouse automation, it’s imperative to consider the following factors:

• System functionality

• Scalability

• Implementation cost and ROI

• Possibility of integration with the existing IT infrastructure

• Experience of the service provider

Not sure where to start warehouse automation and how to digitalize with minimum risks? Contact Computools’s experts in logistics and supply chain at info@computools.com to get a step-by-step guide on warehouse management system implementation.

Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.