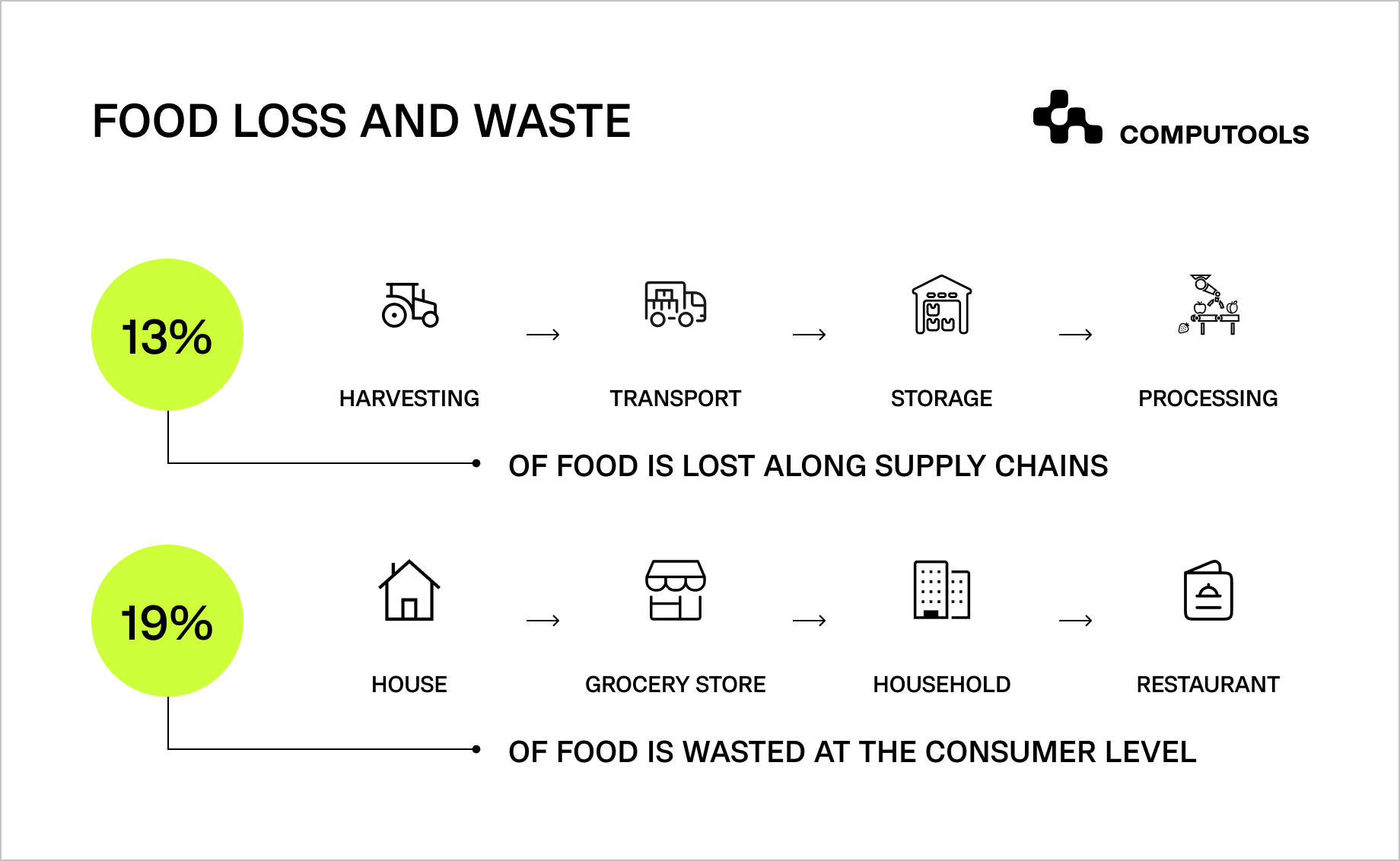

Grocery and retail supply chains face ongoing challenges from food waste, increasing operational costs, and inefficient inventory management. The scale of food loss is staggering: nearly 13% of global production is wasted between harvest and retail.

McKinsey underlines that adopting digital supply chain solutions can directly address this challenge, cutting operating costs by as much as 30%. These figures show why companies are increasingly developing IoT MVP retail solutions: they enable retailers to quickly test connected systems, verify their value, and confidently expand.

Computools supports this transformation through its retail software development services, helping enterprises and mid-sized retailers optimize processes, strengthen customer engagement, and drive measurable ROI. In parallel, our IoT development services enable clients to adopt connected technologies that increase supply chain transparency, improve forecasting, and reduce waste.

We are recognized in IAOP’s Global Outsourcing 100 for five consecutive years and bring technical depth and domain expertise to every IoT MVP project. Having worked on diverse retail and IoT projects, each with unique challenges and goals, we understand there is no one-size-fits-all solution. Real value comes from tailoring every solution to the business’s specific needs.

How Computools helped E-Feller build IoT MVP retail solutions to cut food waste by 75%

One of our clients, E-Feller, a Finnish startup, set out on a mission to reduce food waste across global supply chains by using IoT and advanced digital platforms. The company needed a solution to integrate with IoT devices such as temperature sensors, RFID tags, and GPS trackers to monitor real-time product conditions, location, and expiration dates. They also required tools to forecast demand, optimize inventory, and streamline delivery routes.

Computools’ team developed an IoT MVP, a functional prototype that includes web and mobile applications. This MVP allowed E-Feller to build IoT MVP retail solutions and validate the concept without heavy upfront investments.

The first results were impressive: a 75% reduction in food waste across the supply chain, improved inventory management, and greater logistics efficiency.

This case shows how even a lean MVP approach can create tangible results in grocery and retail by reducing waste, streamlining logistics, and improving overall performance and sustainability.

The following sections outline how to build an IoT MVP for grocery and retail supply chains. We will show the practical steps, technologies, and best practices businesses can follow to modernize operations and achieve lasting results.

How to build an IoT MVP for grocery and retail supply chains

Step 1. Define requirements

Developing an IoT MVP begins with a clear definition of requirements. This stage determines whether your prototype will be practical, scalable, and financially viable. Without it, even the most advanced technology risks failing to deliver value.

Core aspects to consider:

• Power supply: Decide if devices will connect to the power grid, run on batteries, or leverage energy harvesting.

• Connectivity: Choose the proper protocol for your use case, short-range (Bluetooth, NFC) or long-range (LTE, NB-IoT, LoRaWAN).

• Power efficiency: Ensure devices can operate for days or weeks without recharging.

• Latency and bandwidth: Define acceptable delays. Some retail use cases need real-time data, others can tolerate periodic updates.

• Deployment simplicity: Devices should be easy to install and maintain across warehouses, stores, and delivery fleets.

• Early sketches and prototypes confirm durability and usability.

• Financial model: Balance production costs with recurring expenses such as connectivity, cloud hosting, and technical support.

Accurately defined requirements prevent wasted investments and create the foundation for IoT solutions for retail businesses that deliver measurable ROI.

When Computools worked with E-Feller, the challenge of food waste was reframed into precise requirements: battery-powered sensors for flexibility, LTE/NB-IoT connectivity for real-time tracking, and a lean platform architecture that minimized recurring costs.

This approach exemplifies retail innovation with IoT MVPs, where even a small prototype can address a major supply chain problem and prove value early.

Step 2. Create proof-of-concept (PoC)

Once requirements are clear, the next step in IoT MVP development for retail is building a Proof-of-Concept (PoC). A PoC verifies that your concept is technically viable and helps identify potential risks before committing to a full prototype.

At this stage, the focus should be on speed and simplicity. Development kits or single-board computers can be used to test the core functionality. A monolithic backend architecture keeps things straightforward and cost-effective, allowing you to validate features without the complexity of microservices. Running the system on a low-end virtual machine and leveraging free AWS, Google Cloud, or Microsoft Azure tiers helps minimize infrastructure expenses.

It’s also the right moment to stress-test critical elements: antenna placement, connectivity stability, battery life, and compliance requirements such as GDPR or ISO/IEC 27001. Market analysis should run parallel to ensure that the PoC aligns with customer needs and differentiates the product from competitors.

For example, in the E-Feller project, Computools helped validate that IoT sensors could accurately monitor product expiration dates and storage conditions across the supply chain. This confirmation gave confidence to proceed with a functional prototype, ensuring the core idea of reducing food waste could be achieved in practice.

Step 3. Develop a prototype and an MVP for an IoT product

After validating the PoC, the next step is full prototyping. This is where rapid IoT prototyping for retail industry projects turns ideas into working models for real-world testing.

Prototyping identifies weaknesses, uncovers risks, and confirms whether the system works as expected. Depending on objectives, it can range from low-cost “paper prototypes” for UX testing to hardware builds that mirror the final product. Since IoT often involves hardware, even small changes like adding a sensor or altering casing can trigger redesigns and extra costs. To maximize value, businesses should define learning goals clearly and challenge assumptions throughout the process.

Involving multiple stakeholders is also vital: letting end users, engineers, and managers interact with a real model generates insights and early buy-in, which is especially valuable in complex supply chains.

For E-Feller, Computools built a functional prototype of a digital platform with IoT integration. Sensors (temperature, RFID, GPS) tracked expiration dates and logistics data, while the web and mobile apps gave stakeholders visibility into product flow.

The MVP provided real-time monitoring and decision support using technologies like React.js, Redux.js, Recharts.js, and Moment.js. This allowed E-Feller to manage inventory more effectively and prepare for scaling without overinvesting early.

Step 4. Pilot testing and iteration

Building a prototype is only half the journey; the real test begins when it is exposed to real-world conditions. Pilot testing validates how an IoT MVP performs in practice and how stakeholders respond. This stage is essential for measuring impact, gathering feedback, and refining the solution before scaling.

Running pilots for supply chain solutions is complex, so many companies start with “lightweight demos” and limited pilots using real data in a single warehouse or route. This delivers valuable insight without the cost of a full rollout.

Key activities include:

• Selecting pilot scope: Limit testing to one location, route, or product category.

• Integration with systems: Ensure smooth connection with ERP, POS, or warehouse management platforms.

• Measuring KPIs: Focus on waste reduction, inventory accuracy, delivery times, and energy efficiency.

• Iterating based on feedback: Stay open to negative results, as they highlight gaps and potential pivots.

This is where grocery supply chain optimization with IoT proves its value. Real-time monitoring, predictive analytics, and automated decision-making reveal inefficiencies and point to clear cost savings.

In E-Feller’s case, the MVP enabled tracking expiration dates and product flow at different supply chain checkpoints. This immediately improved efficiency: better inventory turnover, optimized logistics, and most importantly, a 75% reduction in food waste. The results validated the concept and encouraged scaling the solution further.

Step 5. Analyze results and scale up

Once pilot testing is complete, the next step is to analyze the results carefully. This is where data becomes the foundation for decision-making, confirming whether the MVP has delivered its promise and is ready to scale.

Essential considerations at this stage:

• ROI evaluation: Compare waste reduction, logistics improvements, and inventory accuracy against MVP development and operating costs.

• Performance metrics: Assess whether sensors, connectivity, and dashboards worked reliably in different conditions.

• Stakeholder adoption: Confirm that warehouse managers, retailers, and distributors find the system practical and beneficial.

• Scalability: Ensure the architecture can handle larger volumes of data, more devices, and wider geographic coverage without losing performance.

This is also the point of transforming an MVP into a complete platform. Companies can build robust retail supply chain IoT solutions that deliver long-term value by iterating on pilot feedback, refining integrations, and adding advanced analytics.

For E-Feller, the MVP’s success became the foundation for a full-scale platform recognized within the food industry. The solution was prepared for expansion to more partners and international markets, strengthening demand forecasting, logistics, and sustainability efforts. What started as a focused MVP evolved into a scalable system that continues to deliver measurable value.

By following these steps and the E-Feller case, retailers can tackle food waste and other challenges, proving rapid prototyping and MVP services as the fastest path to scalable IoT supply chain innovation.

Learn more about MVP approaches in our article: Considering MVP: Why and When It Is Crucial For Business.

Every big innovation starts small. Build an MVP that wins investors and customers.

Real-world examples of IoT innovation in retail and grocery

Up to 30% of perishable goods are lost before reaching consumers, costing businesses more than $1 trillion annually.

At the same time, Gartner reports that over 70% of retailers see IoT as critical for efficiency and transparency. These figures underline the urgency of adopting IoT in grocery supply chain and why global leaders are setting the standard for innovation.

• Amazon. Robots in warehouses and cashier-less Amazon Go stores cut costs and boost convenience through IoT automation.

• Walmart. IoT sensors track refrigeration and HVAC in real time, reducing waste and saving millions in energy and inventory costs.

• Hershey. Smart sensors optimize candy size to reduce material waste, while smart shelves personalize in-store experiences.

• Lululemon. RFID across 300 stores ensures real-time stock visibility and faster fulfillment, winning industry recognition.

• Macy’s. Large-scale RFID boosts inventory accuracy, reduces theft, and drives higher sales.

By studying these use cases, we can identify best practices for developing IoT MVP in retail industry. Whether through startup-focused MVP app development or scaling enterprise platforms, IoT is redefining customer experience, reducing costs, and creating new business models in retail.

IoT in retail: challenges vs. benefits

| Potential Challenges | Business Benefits |

| Lack of IT resources: Smaller retailers often cannot build complex systems in-house. Starting with an IoT-powered MVP for retail company helps test the concept without committing massive budgets. | Scalable innovation: MVPs validate ideas early and can grow into enterprise-grade platforms. Example: E-Feller’s MVP led to a 75% food waste reduction across the supply chain. |

| Security vulnerabilities: Each connected device is a potential weak point. Strong software architecture, reliable hardware, and continuous updates are essential. | Improved security & resilience: Proper IoT design reduces attack surfaces and strengthens trust while enabling safer supply chain automation using IoT |

| Corporate FOMO: Jumping into IoT just to follow competitors wastes money. A smarter path is to focus on the real business problem first. | Data-driven insights: Problem-focused adoption generates actionable analytics. For example, item-level RFID raises inventory accuracy from ~65% to over 95%. |

| Integration with legacy systems: Old POS or ERP tools may resist IoT standards. Careful planning, legacy software modernization, and APIs can bridge the gap smoothly. | Seamless operations: Proper integration boosts supply chain visibility and streamlines inventory control, one reason 59% of retailers use IoT for inventory management. |

| High operational costs: Energy usage and equipment maintenance drain budgets. | Decreased waste & cost savings: Global IoT in the retail market, valued at $57.30B in 2024 and projected to reach $350.85 by 2032 (CAGR 25.9%), proves the economic case for efficiency gains. |

| Rising customer expectations: Traditional in-store tools no longer meet modern standards. | Enhanced customer experience: RFID, AR, and IoT-powered apps help retailers meet demand supported by the 18.8B connected IoT devices expected globally in 2024. |

How to choose the right IoT development partner?

Building an IoT MVP requires the right IoT development partner to turn business goals into scalable solutions.

1. Look for proven experience in retail and grocery supply chains, with expertise in MVP development, hardware–software integration, and compliance with standards like GDPR and ISO.

2. A solid portfolio with measurable ROI, such as reduced waste or optimized inventory, proves that the partner can build IoT MVP retail solutions that deliver results, not promises.

3. Check team capacity: IoT engineers, cloud specialists, data scientists, and whether they offer flexible engagement models. For many businesses, MVP development for startups is the fastest way to validate ideas before scaling.

4. Finally, ensure agile processes, transparent communication, and cultural compatibility so the team works as a valid extension of your business.

To dive deeper into the selection process, from evaluating portfolios and expertise to checking team capacity and cultural fit, read our detailed guide: How to Choose an IoT Software Development Company.

Why Computools?

Computools pairs retail domain expertise with solid engineering to deliver IoT that transforms operations. With 250+ engineers, ISO certification, and Microsoft Partner status, we bring scale and reliability.

Our portfolio spans 20+ grocery retail software development projects from POS and omnichannel to inventory systems and IoT MVPs.

A standout: for E-Feller, we built an IoT-powered MVP that cut food waste by 75% across the grocery chain. Trusted by Visa, Epson, Dior, and Bombardier, we focus on transparent delivery and measurable ROI, from pilots to supply chain automation using IoT at scale.

Email us at info@computools.com to discuss your IoT MVP and explore how we can help you innovate.

Computools

Software Solutions

Computools is an IT consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”