A dramatic transformation now affects supply chain operations because AI solutions have been integrated into the systems. Business leaders find ways to improve logistics management, inventory control, and operational practices through the implementation of artificial intelligence in the supply chain.

AI in supply chain management also affects supply chain operations. The increasing development of AI will create an even larger effect on future operations.

Research indicates that supply chain investments in AI are increasing rapidly as companies plan to spend billions over the next several years. The growing financial commitment displays industry trust in AI’s capabilities in the sector.

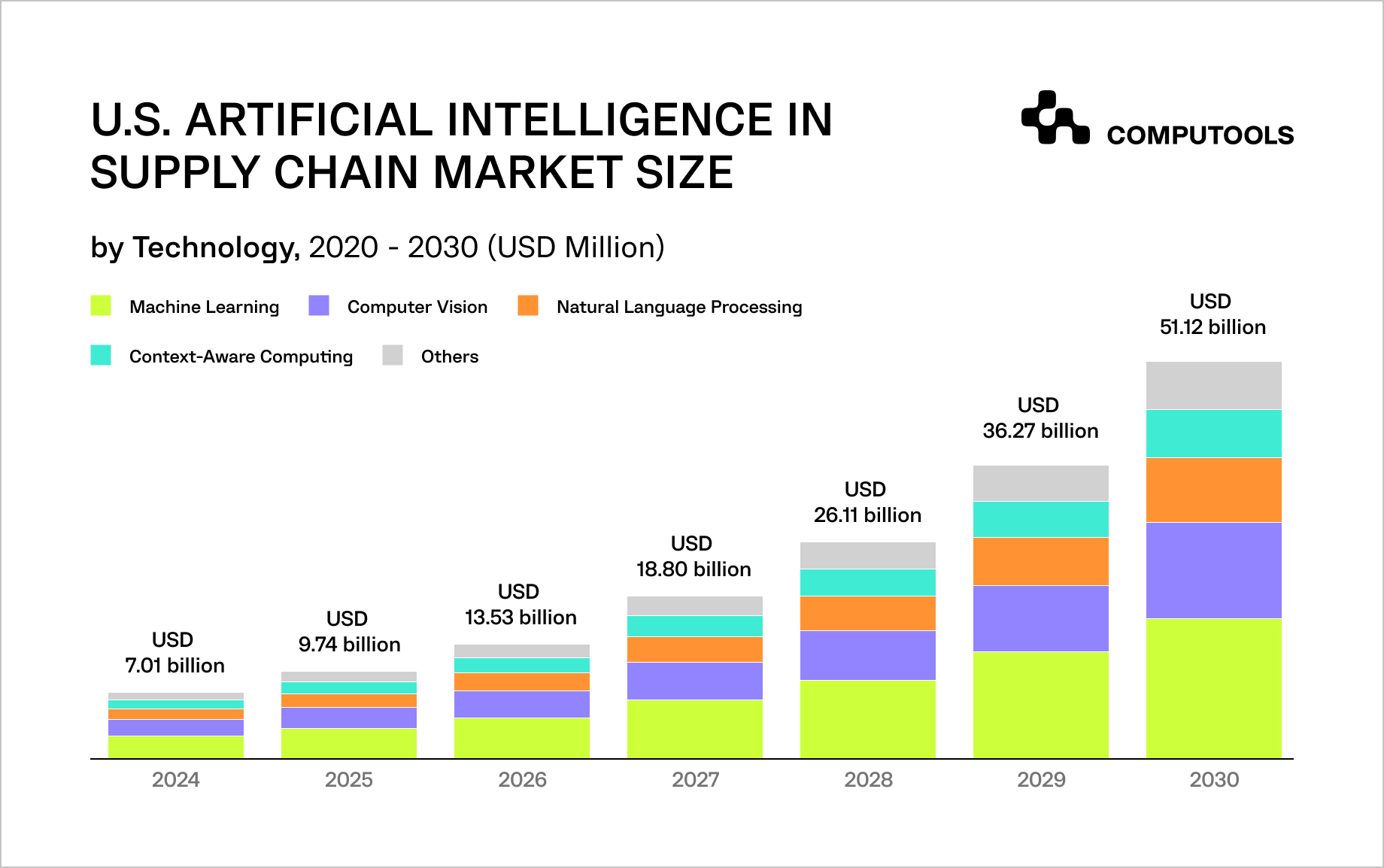

We can see that the AI in supply chain industry was operated at USD 5.05 billion in 2023, and it grew to USD 7.13 billion by 2024 with an estimated 38.9% compound annual growth rate.

On this graph we can observe that the supply chain market for artificial intelligence solutions will increase from USD 5.05 billion in 2023 to USD 51.12 billion by 2030.

Companies achieve exceptional supply chain visibility alongside operational efficiency improvements through the strategic partnership of AI with emerging technologies.

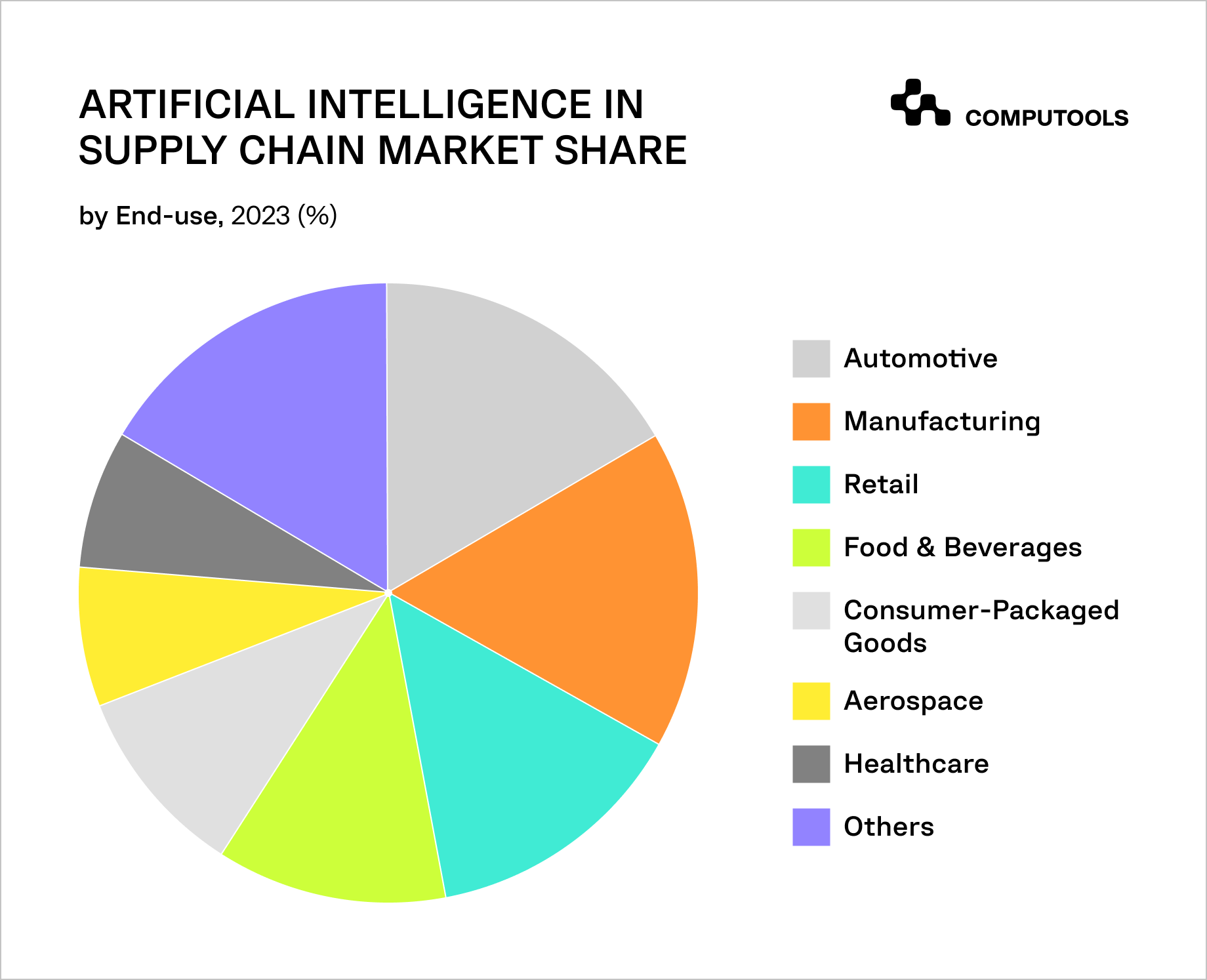

The industries that implement technology are mostly automotive, manufacturing, retail, food and beverages, consumer goods, aerospace and healthcare.

Continue reading this article and discover all the benefits the sector can get, research AI use cases and get some insights for implementation.

Key Benefits of AI in Supply Chain

AI benefits for supply chain are numerous. According to Gartner, some of the most important advantages of AI include:

1. Cost Reduction through AI Optimisation

Machine learning algorithms as part of artificial intelligence tools can help your company achieve optimal inventory control by improving the accuracy of demand forecasting.

To do this, data prediction models rely on historical information and present-day trends to prevent situations where inventory exceeds demand and when items run out of stock.

If you can combine robotic process automation with robots with artificial intelligence, you can reduce your company’s costs for sorting, storing and retrieving goods.

2. Boosting Productivity with Automation

Automation contributes greatly to a company’s productivity. For example, a transportation management system controlled by artificial intelligence enables route planning. As a result, less gasoline is used, and travel times are shortened.

Drones and autonomous mobile robots can be used to carry things more rapidly, efficiently, and without the need for physical labor. Real-time data exchange is also made possible by the interoperability of AI software for supply chain industry with enterprise resource planning systems. You get the foundation for faster decision-making.

3. Enhancing Customer Satisfaction with AI

You can use AI to personalise customer service and make customers more satisfied. With the help of NLP-based algorithms like chatbots and virtual assistants, customer service in supply chains becomes unrivaled.

They can answer questions, track deliveries, and make customised deliveries based on available information. In addition, with the help of artificial intelligence, deliveries are made without disruption and goods are delivered to customers promptly.

4. Improving Forecast Accuracy with Predictive Analytics

It also helps to improve the accuracy of forecasts by predicting the stream of business using statistics. Google Cloud’s BigQuery ML allows predictive models to make precise estimations of the demand for a product.

By applying such a technology to business, one can easily assess and determine business disruptions and adjust them accordingly.

Latest Trends in the AI in Supply Chain Industry

We want to provide you tangible proof of how AI is making its mark in the supply chain, so you can understand these emerging trends more deeply.

1. AI-Driven Digital Twins

Digital twins driven by artificial intelligence in the supply chain market change management. Businesses may view their operations in real-time and perform simulations to make predictions about the future thanks to these virtual representations of tangible assets.

Businesses may carefully monitor their supply chains, make real-time process adjustments, and foresee problems before they occur by utilising sensors and Internet of Things devices from firms such as Siemens and PTC.

For instance, GE use these computerised models to monitor the condition of its machines and forecast when repair is required, thus preventing expensive downtime.

2. Autonomous Warehouses

AI is driving the demand for complete automation in warehouses. Robots and intelligent software are replacing inventory management, sorting, and transferring commodities. One such example is Amazon, which uses robots like Kiva Systems to handle labor-intensive tasks.

These systems employ real-time data to adapt to factors like stock levels and client demand. In an attempt to boost production and reduce human labor, other companies are also joining the trend, including Fetch Robotics and Locus Robotics, which automate everything from picking to packaging.

3. Blockchain and Smart Contracts

Smart contracts and blockchain are improving the supply chain process’s speed, security, and transparency. Once requirements are satisfied, smart contracts take certain actions automatically; no human verification is required.

For instance, IBM’s Food Trust Blockchain makes it possible to trace food goods from farm to table, guaranteeing quality and reducing fraud. Platforms such as VeChain are taking similar measures in sectors like medicine to ensure that items are authentic and reduce counterfeiting.

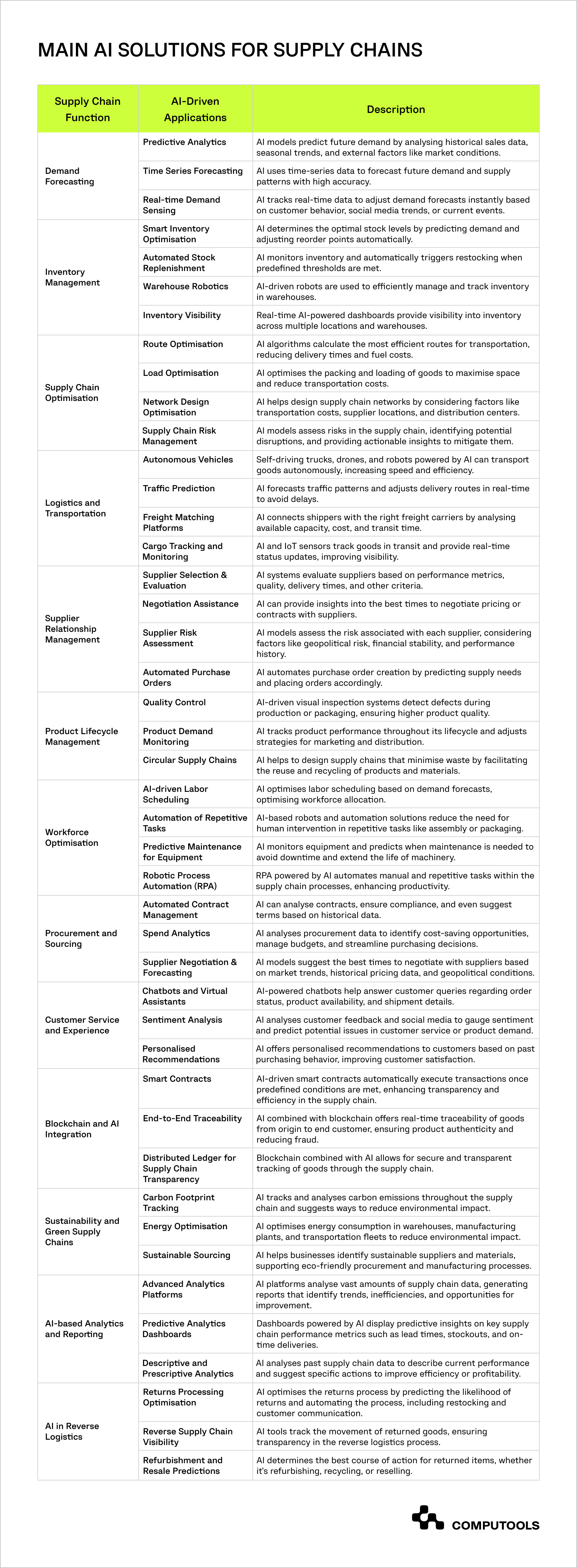

If you want to see the most complete list of AI supply chain solutions of any stage, check our comprehensive spreadsheet.

Regulatory Aspects of AI in Supply Chain

AI integration in the supply chain has become more popular in a number of sectors. However, because of its quick acceptance, suitable regulatory frameworks are now required to handle the operational, ethical, and legal issues that have arisen.

Lets focus on several aspects businesss need to pay attention to:

1. Compliance with Data Privacy Regulations

Supply chain AI implementation requires strict compliance with data privacy rules, especially the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA).

Under the GDPR, companies must collect personal EU resident data compliant with lawful basis principles, specify intended purposes, and provide methods for fulfilling data subject rights. The legal framework demands companies implement rigorous personal data protection methods while establishing proper user consent procedures.

The implementation of data governance strategies enables transparent handling strategies combined with restricted vendor access and ongoing monitoring of external suppliers.

2. Cybersecurity Concerns

Unauthorised parties’ access to AI systems and data breaches result in financial loss and reputational harm to those organisations involved. Due to this situation, regulatory organisations stress the need for strict cybersecurity standards to safeguard AI systems and their associated information.

Companies must conduct recurring security audits and create incident response plans while ensuring their supply chain associates follow security standards.

The EU AI Act demonstrates how regulatory requirements require organisations to maintain security-focused practices that need to continue from the developmental phase through operational deployment and subsequent maintenance phases.

3. Ethical Considerations

Discrimination that disproportionately impacts disadvantaged groups might result from AI systems that magnify biases already present in faulty training data. Supplier managers are directly impacted by this problem, hence it is imperative that AI developers take precautions to avoid prejudice in their work. In order to address these ethical issues, lawmakers are currently creating rules for the proper application of AI.

The reliable AI guidelines from the European Commission encourage businesses to adhere to moral principles by emphasising openness, responsibility, and societal benefit.

Businesses need clear ethical principles to ensure fair and reasonable practices as AI plays a bigger role in supply chain decision-making.

4. Government Oversight and Collaboration

Through executive orders, the Biden Administration has established rules for deploying artificial intelligence systems and has developed steps to increase supply chain dependability in 2023.

Through its efforts to provide standardised ways to address problems, the government exhibits significant initiative.

Challenges of Implementing AI in Supply Chain

Even while AI has the ability to completely transform operations, there are several obstacles to overcome when integrating it into supply chain management. The absence of a defined AI vision is one major barrier.

Only 9% of IT executives have a clear AI vision statement, and only 10% of CEOs say their companies employ AI strategically, according to Gartner.

Organisations find it difficult to match AI projects with business objectives without a clear strategy, which results in less-than-ideal implementation.

1. Data readiness

Effective decision-making in AI-based supply chain systems depends on high-quality, organised data. Data collection, integration, and cleansing are challenges for many businesses, which can result in imprecise insights and subpar automation.

Furthermore, implementing AI is expensive for businesses with tight budgets since it necessitates a large investment in expertise, technology, and ongoing monitoring.

2. Adoption resistance

Supply chain experts used to more conventional approaches can be reluctant to adopt AI-driven procedures.

AI’s contribution to supply chain management is anticipated to increase dramatically in the future. According to Gartner, generative AI will fuel 25% of KPI reporting by 2028.

Furthermore, it is anticipated that intelligent robots would eventually outperform human labor in retail, manufacturing, and logistics, underscoring the trend toward automation.

The growing dependence on AI is further highlighted by the fact that 95% of data-driven choices will be at least partially automated by the end of the year. To optimise AI’s potential in the supply chain, companies must overcome current issues.

A Business Leader’s Guide to Implementing AI in the Supply Chain

Success requires a strategic, well-executed approach.

Follow these key steps to integrate AI effectively:

1. Define a clear AI vision – start by aligning AI initiatives with your business goals.

Ask: How can AI enhance efficiency, reduce costs, or drive growth?

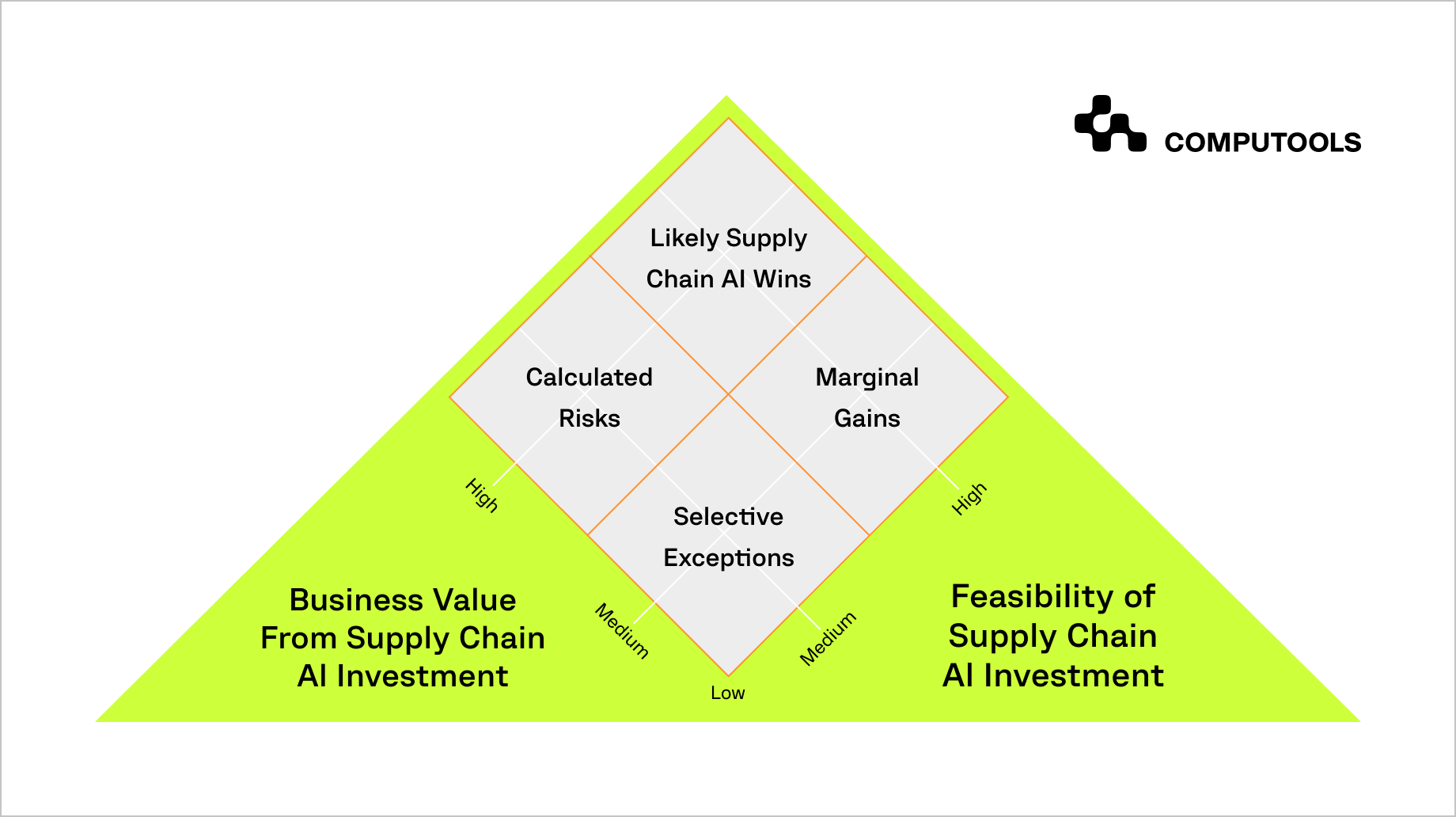

2. Identify high-impact use cases – determine where AI can make the biggest difference.

3. Ensure data readiness – AI thrives on high-quality data.

Invest in:

• Data Collection – Gather relevant, real-time supply chain data.

• Data Cleaning – Remove inconsistencies to improve AI accuracy.

• Data Integration – Connect disparate systems for seamless AI implementation.

4. Adopt a hased approach – avoid full-scale deployment from the start.

Instead:

• Test AI in a controlled environment.

• Track improvements and ROI.

• Expand AI integration based on success metrics.

5. Invest in AI talent & training – building AI capabilities requires expertise.

Consider:

• Bringing in data scientists and AI engineers.

• Training existing staff to work with AI systems.

• Leveraging external expertise for faster adoption.

6. Monitor, optimise & ensure compliance – AI is not a one-time implementation—it requires ongoing improvement.

Business leaders should:

• Regularly assess AI-driven outcomes.

• Continuously update AI algorithms for better accuracy.

• Adhere to data privacy and regulatory requirements.

AI can transform supply chains, but its success hinges on a strategic, step-by-step approach. By defining a clear vision, ensuring data readiness, and continuously optimising AI supply chain solutions, business leaders can drive real impact and stay ahead in an evolving market.

The Role of a Development Partner

The success of using AI in the supply chain may be greatly increased by collaborating with a seasoned AI development company. A development partner ensures smooth integration with current supply chain systems by contributing experience in data management, AI strategy, and bespoke solutions.

Through the identification of possible biases, regulatory compliance, and the optimisation of AI models for optimal efficiency, an AI development partner may also assist organisations in mitigating risks.

They also offer continuous assistance, assisting businesses in adjusting to changing market needs and technological advancements.

Businesses must emphasise strategic deployment and cooperation with development partners as AI transforms supply chain operations in order to remain competitive in an increasingly automated environment.

Why Computools?

The AI in supply chain industry’s use is rapidly evolving. It is cutting expenses and increasing efficiency. Computools can assist you if you want to integrate AI into your supply chain.

We are equipped with the knowledge and experience to assist you at every stage of the procedure, from AI software development services to implementation and beyond.

We offer a range of solutions including AI software solutions, logistics software development, ground transportation solutions, marine transportation software, and custom AI software.

Our portfolio showcases how we develop AI-based supply chain solutions for diverse industries. Our expertise extends to all aspects of development services and we also have expertise in the energy industry.

To find out more about our AI software development services, get in touch with us right now at info@computools.com.

Computools

Software Solutions

Computools is a digital consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”