FASTER DELIVERY OPERATIONS

Average reduction in delivery times achieved through our custom logistics software solutions.

COST SAVINGS

Average operational cost reduction reported by logistics providers using our automated dispatch and route optimization tools.

EXPERTS

100% of our logistics clients partner with us long-term to scale smarter and operate more efficiently.

PROJECTS DELIVERED

Custom logistics software solutions built for freight companies, 3PL providers, and last-mile delivery startups worldwide.

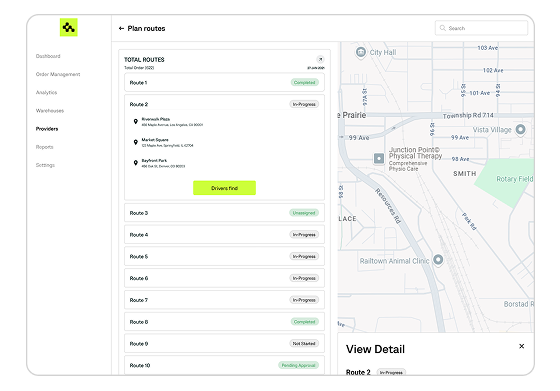

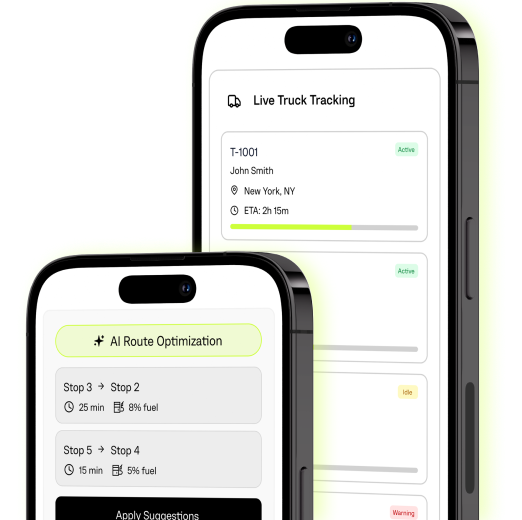

Route Optimization Software

We build advanced Route Optimization Software that uses real-time traffic, delivery constraints, and predictive analytics to calculate the most efficient delivery paths. It enables logistics teams to cut costs, improve on-time performance, and scale operations.

Fleet Tracking Software

We develop real-time Fleet Tracking Software that integrates GPS data, telematics, and delivery milestones to give logistics teams and customers complete visibility into vehicle locations and shipment status, enabling proactive decisions and better service.

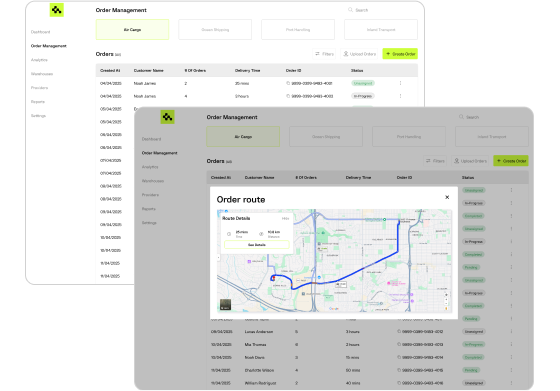

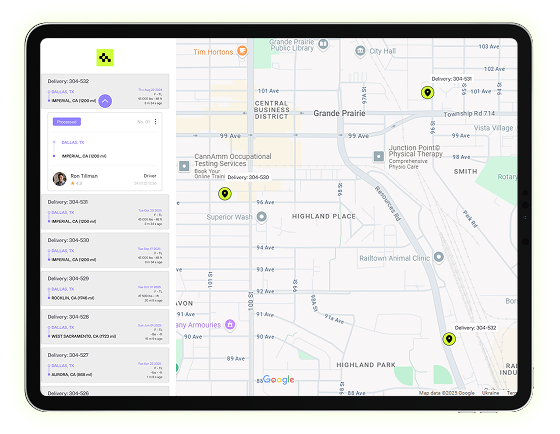

Automated Dispatch Management Software

We build intelligent Dispatch Management Software that eliminates manual guesswork by automating driver assignments, load balancing, and real-time scheduling. This accelerates delivery operations, maximizes fleet efficiency, and unlocks seamless scalability even under peak demand.

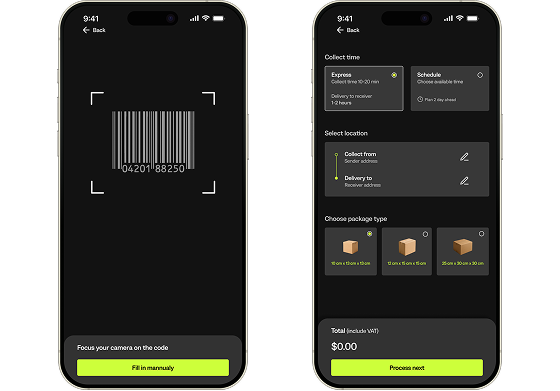

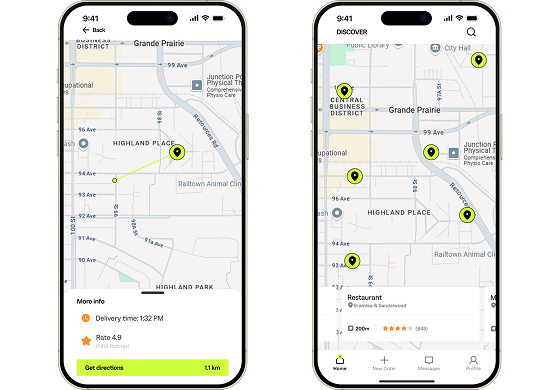

Last-Mile Delivery Optimization Software

We develop Last-Mile Delivery Optimization Software that combines real-time routing, automatic address validation, dynamic delivery scheduling, and integration with tracking systems to maximize accuracy, reduce delays, minimize re-delivery costs, and provide a seamless customer experience that is fast, predictable, and convenient.

Warehouse Management System (WMS)

We build scalable WMS solutions that provide real-time inventory tracking, optimize picking and packing processes, and integrate with your OMS, ERP, and logistics platforms. This reduces errors, increases warehouse efficiency, and speeds up order fulfillment.

Supply Chain Visibility & Management Software

We develop end-to-end Supply Chain Visibility and management Software that unifies data from all suppliers, logistics providers, and systems into one real-time platform. This enables organizations to anticipate disruptions, monitor performance, and make agile, data-driven decisions across the supply chain.

Logistics Automation Software

We create logistics automation solutions that streamline dispatching, invoicing, document processing, and inventory management. These solutions reduce manual labor, speed up operations, and reduce errors. Automated processes and systems integration allow teams to focus on high-value tasks.

Delivery Experience Management Software

We build delivery experience platforms that turn the final mile into a competitive advantage. Our solution provides real-time updates, ETA notifications, live tracking, and integrated feedback tools, creating a transparent, predictable, and customer-friendly delivery journey.

Logistics Compliance Management Software

We develop compliance management platforms that automate customs documentation, validate cross-border requirements, and provide real-time visibility into regulatory status. These platforms help businesses avoid penalties, speed up clearances, and confidently scale global logistics.

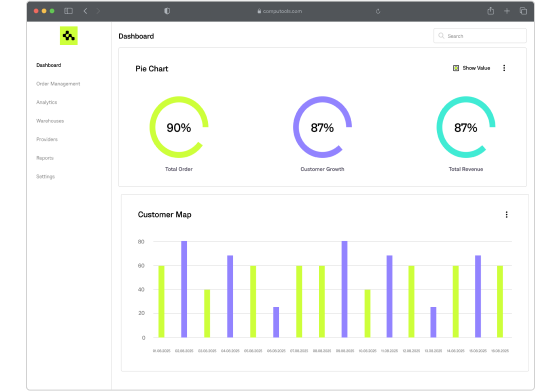

Logistics Analytics & BI Dashboards

We develop powerful logistics analytics platforms that transform fragmented data into real-time, actionable intelligence. By centralizing KPIs across the supply chain, our solutions uncover hidden inefficiencies, accelerate decision-making, and empower teams to boost performance, cut costs, and drive profitable growth.

Route Optimization Software

We build advanced Route Optimization Software that uses real-time traffic, delivery constraints, and predictive analytics to calculate the most efficient delivery paths. It enables logistics teams to cut costs, improve on-time performance, and scale operations.

Fleet Tracking Software

We develop real-time Fleet Tracking Software that integrates GPS data, telematics, and delivery milestones to give logistics teams and customers complete visibility into vehicle locations and shipment status, enabling proactive decisions and better service.

Automated Dispatch Management Software

We build intelligent Dispatch Management Software that eliminates manual guesswork by automating driver assignments, load balancing, and real-time scheduling. This accelerates delivery operations, maximizes fleet efficiency, and unlocks seamless scalability even under peak demand.

Last-Mile Delivery Optimization Software

We develop Last-Mile Delivery Optimization Software that combines real-time routing, automatic address validation, dynamic delivery scheduling, and integration with tracking systems to maximize accuracy, reduce delays, minimize re-delivery costs, and provide a seamless customer experience that is fast, predictable, and convenient.

Warehouse Management System (WMS)

We build scalable WMS solutions that provide real-time inventory tracking, optimize picking and packing processes, and integrate with your OMS, ERP, and logistics platforms. This reduces errors, increases warehouse efficiency, and speeds up order fulfillment.

Supply Chain Visibility & Management Software

We develop end-to-end Supply Chain Visibility and management Software that unifies data from all suppliers, logistics providers, and systems into one real-time platform. This enables organizations to anticipate disruptions, monitor performance, and make agile, data-driven decisions across the supply chain.

Logistics Automation Software

We create logistics automation solutions that streamline dispatching, invoicing, document processing, and inventory management. These solutions reduce manual labor, speed up operations, and reduce errors. Automated processes and systems integration allow teams to focus on high-value tasks.

Delivery Experience Management Software

We build delivery experience platforms that turn the final mile into a competitive advantage. Our solution provides real-time updates, ETA notifications, live tracking, and integrated feedback tools, creating a transparent, predictable, and customer-friendly delivery journey.

Logistics Compliance Management Software

We develop compliance management platforms that automate customs documentation, validate cross-border requirements, and provide real-time visibility into regulatory status. These platforms help businesses avoid penalties, speed up clearances, and confidently scale global logistics.

Logistics Analytics & BI Dashboards

We develop powerful logistics analytics platforms that transform fragmented data into real-time, actionable intelligence. By centralizing KPIs across the supply chain, our solutions uncover hidden inefficiencies, accelerate decision-making, and empower teams to boost performance, cut costs, and drive profitable growth.

Computools builds custom transportation management systems to optimize load planning, carrier selection, freight billing, and real-time shipment tracking for improved logistics efficiency.

We create scalable warehouse management systems that streamline inventory control, picking, packing, order fulfillment, and space utilization across single or multi-location warehouses.

We develop intelligent route planning and dispatch automation tools using real-time traffic data, delivery constraints, and predictive analytics to reduce delays and fuel costs.

We provide fleet management solutions that track vehicle locations, monitor driver behavior, schedule maintenance, and improve overall asset utilization and safety.

Computools delivers last-mile logistics platforms with features like dynamic routing, proof of delivery, ETA tracking, and customer notifications to ensure seamless final delivery experiences.

Computools builds custom logistics CRM software to manage client relationships, automate communication, track sales pipelines, and support collaboration with carriers, vendors, and third-party partners.

Oleg specializes in marine logistics, air cargo ecosystems, and the travel industry helping global air cargo companies, port authorities, and hospitality providers modernize operations through strategic digital innovation.

Oleg Balliiet

VP of Customer Success in Logistics and Travel and Hospitality

For over a decade, Oleg has successfully led our delivery department, ensuring every software solution not only aligns with clients’ strategic goals but also unlocks new growth opportunities and long-term value.

Oleg Svet

Chief Delivery Officer

“The team was very friendly and had the highest level of competence, engagement, and project management.”

“Computools predicted all possible points of our business growth and implemented them into the project.”

“We were highly satisfied with their deep understanding of our fintech processes and their project management was really superb.”

“Computools is a highly professional company with a skilled and responsive team. Their ability to propose valuable improvements and their dedication to the project made a significant difference.”

“The most noteworthy value that stood out was their exceptional experience in developing AI software solutions.”

“We were deeply impressed with their technical expertise, transparency, and flexibility. The team was highly skilled, easy to work with, and always proactive in solving challenges.“

“Computools offered non-standard solutions and maximized their investment in our business success.“

“Our company is impressed by their client-first approach and deep niche expertise.”

“A very comfortable collaboration and clear communication on every stage of platform development and maintenance.”

“After all these years, Computools never fails to arrive on time and with a quality that never ceases to amaze me. They work well as a team and are adaptable and communicative.”

“Within the first three months of its use, the designed program by Computools significantly reduced meter reading fraud by over 30%. Additionally, we saw a rise in operational effectiveness. Customer comments highlighted greater billing transparency and speedier service delivery, which contributed to an improvement in customer satisfaction levels.”

“They were professional, adapted to our short-notice needs, documented everything, and were transparent.”

“Thanks to Computools, we have seen a 15% growth in sales and a 40% boost in user satisfaction. Our image management has become more efficient, and our diagnostic capabilities have improved. Overall, the team has delivered a high-quality solution that meets our requirements.”

“Computools has significantly improved our LMS. The team holds regular meetings and provides detailed project reports, keeping us well-informed. We communicate via email, and overall, everything has gone smoothly.”

“Computools worked closely with us to understand our challenges. They developed a platform that integrated seamlessly with our existing infrastructure and Automatic Identification Systems (AIS) to capture private vessel data.”

“Computools’ work has had a positive impact on the client’s business. The team is flexible and responsive to the client’s needs. Their expertise has been key to the project’s success. Overall, the engagement has been positive.”

“Due to the platform’s use, the new products’ generated go-to-market timeline improves by 20%, cutting down on plan costs and, most importantly, enhancing the connection between the departments. The availability of near real-time information and the enhancement of the speed of decision-making are truly remarkable.”

“Thanks to Computools, we have successfully implemented our system and reduced the need for manual inspections. The team works in regular sprints and keeps us updated on progress. Their personalized approach, ability to listen, adapt, and continuously refine their methods are truly impressive.”

“Computools’ team truly impressed us with their dedication to the project, their ability to adapt to our processes, and their exceptional hard skills. This allowed us to identify many risks in the initial development stages and address some gaps in our processes. Professionalism, contribution, and flexibility are what define Computools. Based on my experience, I strongly recommend Computools for Dedicated Delivery and outsourcing project services!”

“Computools has delivered a functional solution that helped us increase revenue fivefold, reduce costs, and boost productivity. The team efficiently manages tasks in Jira and keeps us updated through weekly calls. Their productive approach and strong work ethic truly stand out.”

“Computools’ technical knowledge is impressive.They delivered the product on time, within the agreed budget, and fully aligned with our requirements.”

“Thanks to Computools’ efforts, we have seen compliance with deadlines and budget and team scalability as needed. The team has a confident project manager who delivers a professional and organized project. Moreover, Computools has quickly onboarded to the project and delivered fast results.”

“Thanks to the new solution, we’ve significantly reduced manual marketing workflows. Computools manages the project effectively, using Scrum methodology to execute tasks efficiently. Their problem-solving skills and ability to anticipate challenges set them apart from other providers.”

“Computools has successfully delivered everything as planned, adding value to the app. The team is highly approachable, tracks progress, and provides real-time updates via Slack. They maintain smooth communication through email and messaging apps, regardless of time zones.”

“Thanks to Computools, we now have an app that integrates 2,000 users into a single platform, significantly reducing the time spent on data exchange between systems and applications. The team manages our collaboration effectively and quickly adapts to changes. Overall, our experience has been highly successful.”

“Computools has been responsible for creating a novel database and front-end solution, incorporating both the development portal for digital standards and a modern shop for the sale of these standards. Throughout the course of the project, we have been consistently impressed by the professionalism exhibited by the Computools team, as well as their detailed understanding of our client’s processes. Their expertise, commitment to our objectives, and consistent delivery of high-quality work are notable aspects of their service.”

“Thanks to Computools, the client saw a 35% increase in daily active users and a 25% rise in user retention rates. The Android app also saw a 20% reduction in load times. User feedback indicated high user satisfaction; the feedback highlighted the product’s enhanced navigation and content linkage.”

“They are some of the best software developers I ever had the privilege to work with. Among other skills, their project scope and time estimation are very good and when wrong will work around the clock to make the date especially if it has business consequences. Not only are they amazing software developers, but they are also great people to work with. I am in awe seeing their devotion.”

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”

“After analyzing our requirements, Computools outlined potential solutions and deadlines for each stage. They designed the user flows and defined the user personas. They built the platform infrastructure and oversaw its implementation. Once we finished development, we conducted usability tests to assess their submitted work. Computools led an organized, agile team that adapted to our evolving needs. They listened to our feedback and managed their time well throughout the project.”

“The application perfectly meets the large-scale demands of the project, with the team creating an effective solution that works well and provides the required level of control. They were communicative, responsive, and proactive throughout the project, demonstrating their experience at all times.”

“The Computools team came to us with ideas, and that’s unusual. I’m satisfied that they gave us the right recommendations which are contemporary and relevant for today’s users. Because with other companies on previous projects, it was like pulling teeth to get them to make suggestions. The product received positive feedback even before being implemented and has led to significant customer and revenue growth.”

“We had to meet a significant increase in the development, so we needed to scale up relatively quickly but cost-effectively. The result definitely meets our expectations. The completed project received positive feedback for features and overall design. They’re very organized from a project management perspective and they’re technically competent. We appreciated their innovativeness, professionalism, and great communication skills. ”

“Their team has given us strong learning opportunities, and their developers are accommodating and collaborative.”

“We’re satisfied with the quality of work Computools deliver. They listen and try to understand our needs instead of finding new ways to charge us. We appreciate their transparent work structure. They kept us up-to-date regarding their progress throughout the entire development cycle. Knowing the system’s status throughout the coding process put my mind at ease.”

“They are very accommodating. They have very talented people. I’ve worked with hundreds of overseas developers and it’s not normal to have such excellent overseas developers. I don’t have to babysit Computools. They speak great English. They’ve also really helped with making suggestions on how to improve the product.

When we first launched our product at the beginning of the year, we were at 30,000 users a month and now we’re at 70,000. The bump in users is a result of the increased option rate and the new toys that Computoolls have built for me.”

“Computools developed software for our business to help automate our processes. Their team is very easy to speak to over Skype, where I can speak directly to a designated client manager, project manager, and the development team.”

“They were able to reduce the customer entry acquisition process from 2–3 weeks to 48 hours and have completely optimized all business processes. They’re a trustworthy company, full of integrity and great principles. They also communicate well in spite of the distance and resolve problems quickly.”

“They have a very positive attitude, which I enjoy a lot, and their technical skills are impressive. During this project, I got acquainted with their VP in charge of technical development, and he’s very impressive. Technologically, they are on the cutting edge of what they do. They use a lot of interesting technologies, which is good.”

Chief Delivery Officer

Transform your business with our technology expertise in creating vehicle tracking software, custom dispatch and carrier management digital solutions and logistics mobile apps.

Drive profitability in your business with maritime transportation management systems and integrated logistics software designed by Computools.

Increase your business accuracy with custom warehouse management systems, powerful inventory management solutions, and intuitive warehouse mobile applications tailored to maximize your team productivity.

Gain a competitive edge and deliver technical value to your business with advanced air freight management software, air cargo management systems, and real-time cargo monitoring apps built by our team.

Computools delivers custom logistics software solutions, including fleet management systems, warehouse automation, supply chain tracking, and transportation management software tailored to optimize logistics operations.

By leveraging real-time data analytics, IoT integration, and automation, Computools creates logistics software solutions that streamline operations, reduce costs, and improve delivery times across your supply chain.

Yes, our team builds scalable and flexible supply chain management software designed to adapt to growing business needs and integrate seamlessly with existing logistics infrastructure.

Yes, Computools provides custom maritime software development services for shipping companies, port operators, and marine logistics providers. Our solutions include vessel tracking systems, port management software, and cargo scheduling tools that enhance maritime logistics efficiency, ensure compliance with international maritime regulations, and optimize marine fleet operations.

We employ advanced technologies such as cloud computing, AI, machine learning, GPS tracking, and blockchain to develop innovative and secure logistics software tailored to your business.

Development time varies by project, but typically Computools delivers custom transportation management software within 4 to 8 months, including analysis, design, development, testing, and deployment.